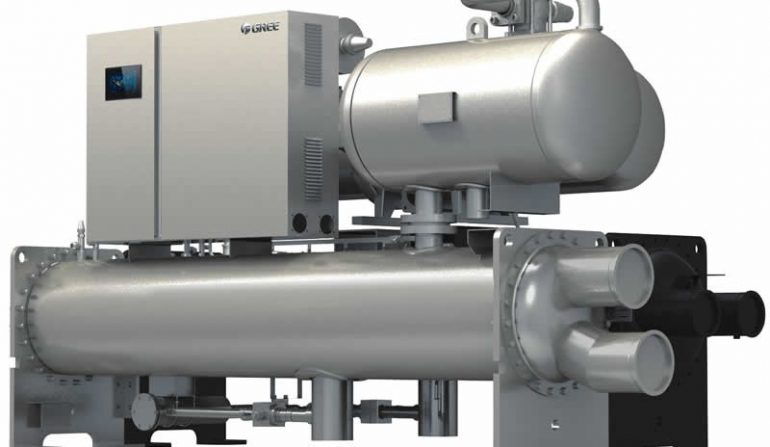

Dairy Chiller Selection Guide

Dairy Chiller Selection Guide

Selecting the correct dairy chiller is crucial for maintaining the quality and safety of dairy products whereas guaranteeing proficient and dependable operation. Diary Chiller Selection Guide : Here’s a comprehensive guide to help you select the best dairy chiller for your particular needs:

Cooling Capacity:

Determine the desired cooling capacity based on components such as the volume of drain to be cooled, the rate of milk production, and any future extension plans. Select a chiller with sufficient capacity to handle peak cooling loads during peak production periods.

Temperature Control:

Select a chiller with precise temperature control capabilities to preserve the milk at the required capacity temperature, typically between 2°C to 4°C (35.6°F to 39.2°F). Ensure that the chiller can maintain stable temperatures inside tight resistances to avoid spoilage and ensure item quality.

Hygienic Design:

Select a dairy chiller with a hygienic design highlighting smooth surfaces, corrosion-resistant materials, and easy-to-clean components to meet strict cleanliness requirements in dairy handling. Consider highlights such as stainless steel development, consistent welds, and removable panels for easy access and cleaning.

Energy Efficiency:

Look for energy-efficient dairy chillers that can offer assistance reduce working costs and minimize environmental impact. Select chillers with high-efficiency compressors, variable-speed drives, and advanced control calculations to optimize energy consumption whereas maintaining exact temperature control.

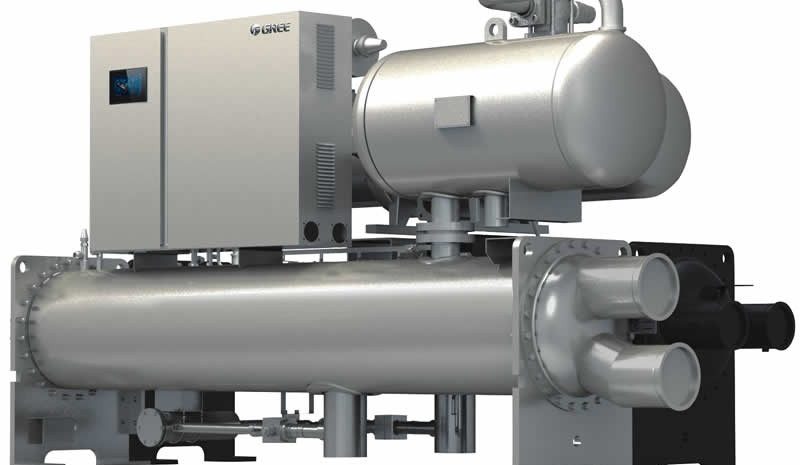

Reliability and Durability:

Select a dairy chiller with a robust construction and dependable components to guarantee long-term execution and minimize downtime. Select reputable brands known for their reliability, and consider highlights such as durable refrigeration systems, heavy-duty pumps, and corrosion-resistant coatings.

Compliance with Regulations:

Ensure that the dairy chiller complies with administrative guidelines and guidelines administering dairy preparing and food safety, such as the Pasteurized Milk Ordinance (PMO) within the United States. Select chillers that meet industry-specific requirements and are approved for utilize in dairy applications.

Ease of Installation and Maintenance:

Choose a dairy chiller that’s simple to install, work, and maintain to minimize downtime and maintenance costs. Look for highlights such as plug-and-play installation, intuitive controls, and easy-access service points for schedule maintenance and investigating.

Remote Monitoring and Control:

Consider dairy chillers with remote monitoring and control capabilities that permit you to monitor temperature levels, working parameters, and execution measurements remotely. Inaccessible get to enables real-time checking, proactive maintenance, and convenient intervention in case of system abnormalities or faults.

Support and Service:

Select a dairy chiller from a reputable producer or provider that gives solid client support, technical help, and after-sales benefit. Select providers with a proven track record of customer satisfaction and prompt reaction to service requests.

Budget and Total Cost of Ownership:

Assess the starting cost, working costs, and total fetched of possession (TCO) of the dairy chiller over its expected lifespan. Consider components such as energy efficiency, support necessities, warranty coverage, and potential savings in item losses or downtime.

By following this dairy chiller selection direct and considering these key factors, you’ll be able select the proper chiller system that meets your dairy preparing needs whereas guaranteeing item quality, safety, and efficiency.