How Plate Heat Exchangers Work: A Simple Guide to Heat Transfer

How Plate Heat Exchangers Work: A Simple Guide to Heat Transfer

Plate heat exchangers (PHEs) are imperative components in numerous industrial and HVAC applications due to their effectiveness and compact plan. Understanding how they work can offer assistance in selecting, working, and maintaining these gadgets. Here’s a basic guide to how plate heat exchangers work, A simple guide to heat transfer :

What may be a Plate Heat Exchanger?

A plate heat exchanger comprises of different lean, corrugated metal plates stacked together. These plates make a arrangement of channels through which hot and cold liquids can stream, separated by the plates to anticipate mixing. The essential work of a PHE is to transfer heat from one fluid to another effectively.

Key Components of a Plate Heat Exchanger

1. Plates: The center of the PHE, more often than not made from stainless steel or other corrosion-resistant materials. The plates have a wavy or layered design to extend the surface range and turbulence, upgrading heat transfer.

2. Gaskets: Rubber seals that anticipate the liquids from mixing and guarantee they stream through designated channels.

3. Frame: Holds the plates together, usually with bolts or clamps. It incorporates conclusion plates and carrying bars to support and align the plates.

4. Inlets and Outlets: Ports through which the hot and cold liquids enter and exit the PHE.

How Does Heat Transfer Happen?

1. Fluid Entry:

- Hot fluid enters the PHE through one set of channels.

- Cold fluid enters through another set of inlets on the inverse side.

2. Flow Arrangement:

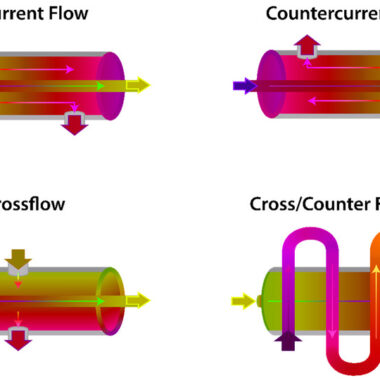

The liquids flow in alternate channels made by the plates. Regularly, a counterflow course of action is utilized, where the hot and cold fluids stream in opposite directions. This maximizes the temperature difference and makes strides heat transfer proficiency.

3. Heat Exchange:

- As the hot fluid streams over one side of a plate, it transfers heat through the metal plate to the cold fluid on the inverse side.

- The layered design of the plates increments surface range and turbulence, enhancing the rate of heat transfer.

4. Temperature Equilibration:

- The hot fluid cools down because it transfers its heat to the cold fluid.

- The cold fluid heats up because it retains heat from the hot fluid.

5. Fluid Exit:

- The cooled hot fluid exits the PHE through the outlet.

- The heated cold fluid exits through its particular outlet.

Advantages of Plate Heat Exchangers

1. High Efficiency: The huge surface zone and turbulence made by the plates result in fabulous heat transfer productivity.

2. Compact Plan: PHEs have a tall heat transfer coefficient, permitting for a compact plan compared to shell-and-tube heat exchangers.

3. Adaptability: Plates can be effortlessly included or removed to adjust the capacity of the heat exchanger.

4. Simple Maintenance: The plan permits for simple disassembly for cleaning and review.

Applications of Plate Warm Exchangers

1. HVAC Systems: Proficiently transfer heat between different building heating and cooling circuits.

2. Food and Beverage Industry: Utilized for pasteurization and cooling forms.

3. Chemical Processing: Utilized for heating and cooling chemical arrangements.

4. Power Generation: Utilized for recouping waste heat from different forms.

Conclusion

Plate heat exchangers are productive, flexible, and easy-to-maintain devices utilized in a variety of applications. By understanding the essential principles of how they work, you’ll better appreciate their value in optimizing thermal processes and improving energy efficiency.

Discuss modes of heat transfer - Cool Fab Equipments July 03, 2024 at 12:46 pm

[…] affecting everything from the weather to the way we cook our food. There are three essential modes of heat transfer: conduction, convection, and radiation. Let’s explore and discuss modes of heat transfer in […]