Illustrate the role of fluid flow and surface area in heat exchangers

Illustrate the role of fluid flow and surface area in heat exchangers

Heat exchangers are devices outlined to effectively transfer heat from one fluid to another. They are broadly utilized in different businesses, counting control era, refrigeration, air conditioning, and chemical preparing. Two basic components affecting the execution of heat exchangers are fluid stream and surface area. Illustrate the role of fluid flow and surface area in heat exchangers : Let’s dig into their parts and how they influence heat exchange effectiveness.

The Part of Fluid Flow

1. Fluid Flow Rate

The flow rate of fluids through a heat exchanger altogether impacts its productivity. Here’s how:

Higher Flow Rate : Expanding the flow rate of fluids can improve the heat transfer rate. This can be since a better flow rate decreases the thermal boundary layer thickness on the heat exchanger surfaces, permitting for more effective heat transfer. Be that as it may, too much tall flow rates can lead to expanded weight drops and energy utilization.

Lower Flow Rate : Bringing down the flow rate decreases the heat transfer rate as the fluids spend more time within the heat exchanger, but this could lead to a thicker thermal boundary layer and diminished generally heat transfer productivity.

2. Flow Designs

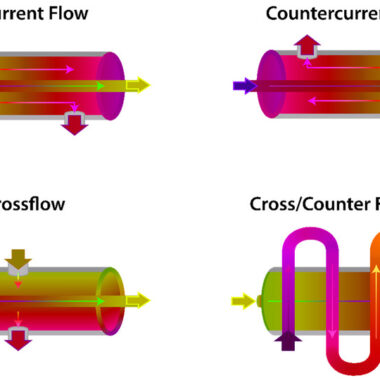

The arrangement of fluid flow in a heat exchanger is vital for its execution:

Counter-Flow : In a counter-flow heat exchanger, the fluids stream in inverse directions. This configuration maximizes the temperature gradient between the fluids, driving to more effective heat transfer. It’s the most productive stream course of action.

Parallel-Flow : In a parallel-flow heat exchanger, both fluids flow within the same course. Whereas less difficult to plan and construct, this course of action is less effective than counter-flow since the temperature gradient diminishes along the length of the exchanger.

Cross-Flow : In cross-flow heat exchangers, fluids flow opposite to each other. This plan is common in applications like radiators and air conditioning units. Whereas not as effective as counter-flow, it offers a good adjust between performance and plan complexity.

The Part of Surface Area

1. Heat Transfer Surface Range

The surface area accessible for heat exchange directly influences the proficiency of a heat exchanger:

Increased Surface Area : A bigger surface range gives more space for heat exchange to happen between the fluids. Usually frequently accomplished by utilizing fins, layered surfaces, or numerous tubes within the plan. More surface range implies higher heat transfer rates, moving forward the generally proficiency of the exchanger.

Optimizing Surface Region : It’s fundamental to optimize the surface range to adjust cost, measure, and efficiency. Whereas expanding surface range generally progresses heat transfer, it can too lead to higher fabric and fabricating costs.

2. Surface Characteristics

The nature of the heat exchanger surface moreover plays a part:

Smooth vs. Rough Surfaces : Smooth surfaces are easier to clean and maintain but might offer lower heat transfer rates compared to rough or finished surfaces, which can improve turbulence and move forward heat transfer productivity.

Material Choice : The fabric of the heat exchanger influences its thermal conductivity. Metals like copper and aluminum are commonly utilized due to their tall thermal conductivity, which encourages superior heat transfer.

Practical Applications and Considerations

In down to earth applications, both fluid flow and surface region must be carefully considered and optimized to guarantee effective heat exchange. For instance:

Automotive Radiators : Utilize cross-flow plan with fins to increase surface region, permitting for effective cooling of the engine coolant.

Industrial Heat Exchangers : Frequently utilize counter-flow arrangements and increased surface range (e.g., through finned tubes) to maximize productivity in forms like power generation and chemical production.

HVAC Systems : Utilize cross-flow or counter-flow designs with optimized surface regions to guarantee effective heating or cooling of air.

Conclusion

The performance of heat exchangers is significantly affected by fluid flow and surface region. By optimizing these variables, engineers can design heat exchangers that give proficient and compelling heat transfer for different applications. Whether it’s upgrading the flow rate, choosing the proper stream design, or expanding the heat transfer surface region, each choice plays a vital part in accomplishing ideal heat exchanger execution.