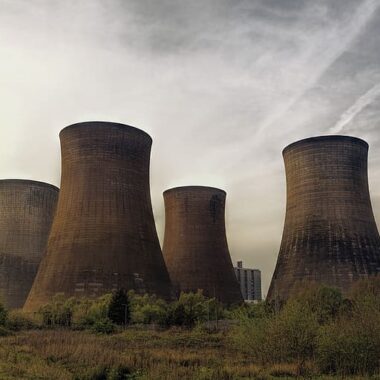

Zero-Liquid Discharge Cooling Towers

Introduction

Zero-Liquid Discharge cooling towers are designed to address the growing concerns over water scarcity and environmental impact by eliminating wastewater discharge from cooling processes. Traditional cooling towers rely on a continuous supply of water for evaporation and use blowdown to remove dissolved solids, which leads to significant water loss and environmental concerns. ZLD systems, however, employ advanced technologies to recycle and reuse the water within the cooling tower, leaving behind no liquid waste.Eco-Friendly Cooling Towers

How ZLD Cooling Towers Work

- Water Treatment and Recycling:

ZLD cooling towers incorporate a series of water treatment processes, including filtration, reverse osmosis, and ion exchange, to remove impurities and dissolved solids from the cooling water. This treated water is then reused in the cooling process, significantly reducing water consumption. - Evaporation and Crystallization:

The concentrated brine from the water treatment process is further treated through evaporation and crystallization technologies. These systems evaporate the remaining water, leaving behind solid waste, which can be safely disposed of. This ensures that no liquid waste is discharged into the environment. - Condensate Recovery:

ZLD cooling towers are often equipped with condensate recovery systems that capture and reuse water vapor produced during cooling. This additional step helps maximize water efficiency by capturing water that would otherwise be lost to the atmosphere.

Benefits of Zero-Liquid Discharge Cooling Towers

- Water Conservation:

ZLD cooling towers drastically reduce the need for freshwater intake by recycling nearly all of the water used in the cooling process. This is particularly beneficial in regions facing water scarcity or strict water usage regulations. - Environmental Protection:

By eliminating liquid waste discharge, ZLD systems prevent the release of harmful chemicals and contaminants into the environment. This minimizes the risk of soil and water pollution, supporting more sustainable industrial practices. - Regulatory Compliance:

Many industries are subject to stringent environmental regulations regarding water usage and discharge. ZLD cooling towers help companies comply with these regulations by ensuring zero wastewater release, avoiding potential fines and penalties. - Operational Efficiency:

ZLD systems not only conserve water but also improve the overall efficiency of the cooling tower. With less blowdown and makeup water required, the operational costs associated with water procurement and treatment are significantly reduced. - Cost Savings:

Although the initial investment for ZLD systems may be higher, the long-term cost savings from reduced water usage, lower wastewater disposal fees, and compliance with environmental regulations make it a cost-effective solution over time.

Applications of ZLD Cooling Towers

- Power Plants:

Power generation facilities often face high water usage demands and strict environmental regulations. ZLD cooling towers help these plants reduce their environmental footprint and ensure continuous operation in water-scarce regions. - Petrochemical Industries:

Petrochemical plants require significant cooling capacities and produce wastewater containing various contaminants. ZLD cooling towers enable these facilities to manage their water use more sustainably and meet stringent discharge regulations. - Food and Beverage Processing:

Industries like food and beverage processing can benefit from ZLD systems by minimizing water consumption and ensuring compliance with hygiene and environmental standards. - Mining and Metals:

Mining operations often occur in arid regions where water is a scarce resource. ZLD cooling towers allow these facilities to reduce water consumption and mitigate environmental impacts associated with wastewater disposal. - Textile Manufacturing:

The textile industry, known for its high water usage and wastewater generation, can utilize ZLD cooling towers to recycle water and reduce environmental impact, making their processes more sustainable.

Conclusion

Zero-Liquid Discharge cooling towers offer a sustainable and eco-friendly solution to the challenge of water scarcity, particularly in water-intensive industries. By recycling and reusing water within the cooling system, ZLD technology not only conserves precious water resources but also helps industries meet regulatory requirements and reduce their environmental impact. Despite the initial investment and operational complexities, the long-term benefits make ZLD cooling towers an attractive option for forward-thinking industries committed to sustainable practices.