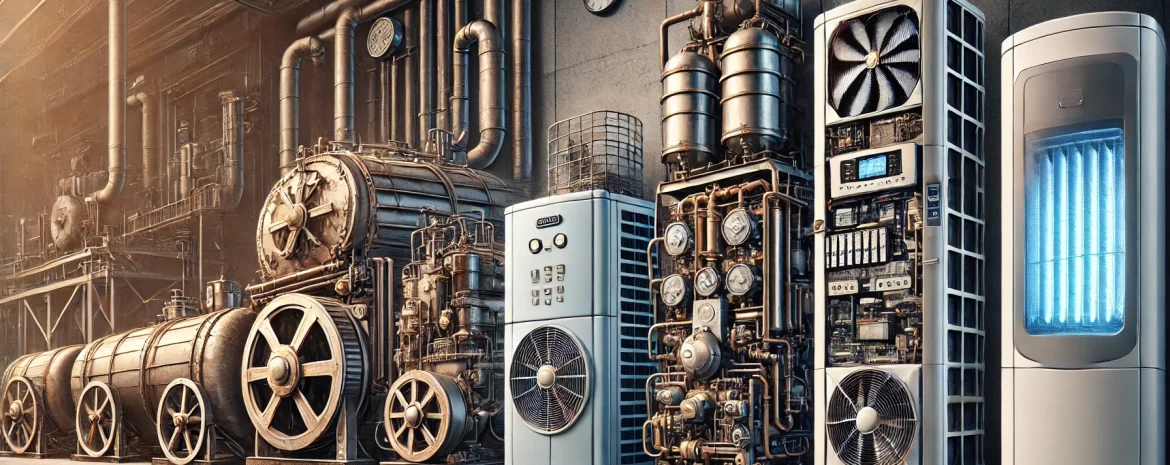

Evolution of Chiller Technology

Introduction

Evolution of Chiller Technology has dramatically transformed the landscape of cooling systems, moving from basic mechanical setups to advanced, intelligent solutions. Traditional chillers once operated with manual controls and fixed-speed compressors, often resulting in energy inefficiencies. Today, with the integration of smart sensors, IoT, and variable-speed drives, modern chillers provide real-time monitoring, adaptive cooling capabilities, and enhanced efficiency. This evolution reflects the industry’s shift toward sustainability, automation, and precise climate control, making chillers more adaptable and efficient for various applications across industries.

Traditional Chiller Systems: The Foundation

- Basics of Traditional Systems: Early chiller systems relied on mechanical components and basic control mechanisms to regulate temperature. These chillers were typically centralized units, manually controlled, and operated with set points that weren’t flexible.

- Energy Intensity: Traditional chillers consumed significant energy, often running continuously even when demand was low, leading to inefficiency. Without advanced monitoring, these systems lacked real-time optimization and responsiveness.

- Maintenance Challenges: Maintenance involved manual inspections and scheduled servicing. Fault detection was reactive, often occurring after performance had already been compromised, resulting in higher downtime and increased operational costs.

Introduction of Variable Speed Drives (VFDs)

- Energy Efficiency Improvement: One of the first major technological shifts in chiller technology was the introduction of VFDs. These allowed chillers to adjust compressor speeds based on real-time cooling demand, significantly reducing energy consumption.

- Optimized Performance: With VFDs, chillers could operate more efficiently during part-load conditions, leading to lower power consumption and improved system reliability.

Integration of Automation and Advanced Controls

- PLC and SCADA Systems: As control systems advanced, chillers began integrating programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems, allowing operators to monitor and adjust operations remotely.

- Precise Monitoring: These systems enabled better data collection, offering insights into performance metrics such as energy use, temperature regulation, and operational status. This helped improve reliability and optimize cooling load distribution across systems.

The Rise of Smart Chillers

- IoT and Connectivity: Smart chillers, embedded with IoT sensors and connected via cloud networks, represent the pinnacle of modern cooling technology. These chillers collect real-time data on temperature, pressure, and flow rates, allowing operators to monitor and control operations remotely from any location.

- Real-Time Analytics: Advanced analytics powered by AI and machine learning help optimize chiller performance, predict potential issues before they occur, and reduce energy wastage. Smart chillers are able to dynamically adjust to environmental conditions, cooling loads, and building occupancy levels.

- Predictive Maintenance: The incorporation of AI enables predictive maintenance, which reduces unplanned downtime and extends the operational lifespan of the chiller. With real-time monitoring, issues are identified and addressed before they escalate, ensuring continuous performance.

Energy Efficiency and Environmental Impact

- Reduction in Carbon Footprint: Modern smart chillers are designed to comply with stricter environmental regulations, including the use of eco-friendly refrigerants and energy-efficient technologies. These systems help organizations meet sustainability goals while significantly reducing their carbon footprint.

- Energy Savings: Compared to their traditional counterparts, smart chillers offer up to 30-50% energy savings by optimizing load distribution, minimizing unnecessary energy consumption, and leveraging renewable energy sources where possible.

Sustainability and the Future of Chiller Technology

- Net-Zero Emissions Target: The next wave of innovation in chiller technology will focus on achieving net-zero emissions through advanced refrigerants, enhanced energy recovery, and integration with renewable energy sources like solar or wind power.

- Adaptive AI Technologies: Future smart chillers are expected to employ even more sophisticated AI systems that learn building patterns, weather conditions, and energy demand forecasts, optimizing performance in real time.

Emergence of Heat Recovery Chillers

- Waste Heat Utilization: Heat recovery chillers became popular as they allowed facilities to capture and reuse waste heat generated during the cooling process. This dual-purpose function improves efficiency by providing both cooling and heating solutions without additional energy input.

- Increased Efficiency: By utilizing waste heat for space heating or preheating water, these chillers reduced the overall energy consumption of buildings, making them a highly effective solution in energy-conscious industries.

Magnetic Bearing Chillers: Reducing Friction

- Frictionless Operation: Magnetic bearing technology eliminated the need for lubricated bearings, reducing mechanical wear and friction. This technology not only enhanced energy efficiency but also minimized maintenance costs.

- Quieter Performance: Magnetic bearing chillers run much quieter than traditional models due to the absence of physical contact between moving parts, making them ideal for noise-sensitive environments like hospitals or office buildings.

Introduction of Hybrid Chillers

- Combining Technologies: Hybrid chillers integrate the functionality of both air-cooled and water-cooled chillers, offering flexibility depending on the operational environment and cooling load. These systems switch between modes to maximize energy efficiency.

- Water Conservation: By using air-cooled modes when possible, hybrid chillers reduce the need for water, which is especially beneficial in regions facing water scarcity.

Modular Chiller Systems

- Scalability: Modular chillers introduced a new level of scalability, allowing facilities to add or remove chiller units based on demand. This reduced upfront capital costs and allowed for more precise cooling capacity adjustments as the business grows.

- Minimized Downtime: In modular systems, the failure of one module does not lead to complete system failure, making maintenance easier and preventing major disruptions.

Multi-Stage Compressors

- Higher Efficiency at Part Load: Multi-stage compressors offer greater efficiency by using multiple stages of compression, which allows for optimized energy usage, particularly during partial load conditions. This helps to significantly lower operational costs.

- Improved Reliability: These compressors reduce the strain on individual components by distributing the workload across stages, increasing the overall lifespan of the chiller system. Evolution of Chiller Technology

Conclusion

Evolution of Chiller Technology from traditional, energy-intensive systems to smart, AI-driven solutions marks a major leap in industrial cooling. Smart chillers not only improve operational efficiency but also significantly reduce energy consumption and environmental impact. As technology continues to advance, the role of smart cooling systems will become even more prominent, ensuring sustainability and future-proofing critical industrial processes.