Nanomaterials in Heat Exchanger

Introduction

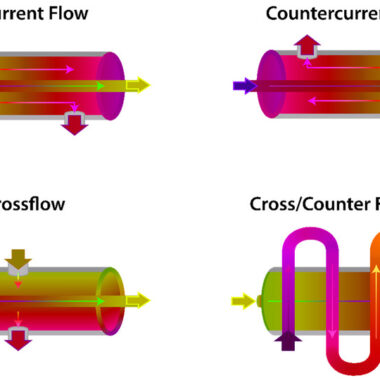

Nanomaterials in Heat Exchangers are transforming the landscape of thermal management systems, offering remarkable improvements in efficiency and performance. These advanced materials, composed of nanoparticles with exceptional thermal conductivity, have the ability to enhance heat transfer rates significantly. By incorporating nanomaterials into heat exchanger designs, industries can achieve better thermal control, reduce energy consumption, and extend the lifespan of equipment. Whether used to optimize cooling or heating processes, nanomaterials enable more compact, lightweight, and efficient heat exchangers, paving the way for innovation in sectors ranging from electronics to energy.

- Enhanced Thermal Conductivity: Nanomaterials, such as graphene and carbon nanotubes, offer much higher thermal conductivity compared to traditional metals, enabling faster and more efficient heat transfer. This reduces the temperature gradients within the heat exchanger, leading to a more uniform temperature distribution.

- Compact and Lightweight Designs: With nanomaterials providing superior thermal performance, heat exchanger systems can be designed more compactly without compromising efficiency. This is particularly valuable in applications where space and weight are critical factors, such as in aerospace or automotive industries.

- Nanofluids for Superior Heat Transfer: Nanofluids, which are fluids infused with nanoparticles, significantly improve the thermal properties of the working fluid. These nanofluids enhance the convective heat transfer coefficient, allowing for better heat exchange between the fluid and the surface of the exchanger.

- Reduced Energy Consumption: Heat exchangers with advanced nanomaterials can operate at lower energy levels due to their improved thermal conductivity. This reduction in energy consumption is beneficial for industries looking to minimize their environmental footprint and reduce operational costs.

- Improved Durability and Lifespan: Nanomaterials also contribute to the durability of heat exchangers. Many of these materials offer superior resistance to corrosion, wear, and fouling, extending the lifespan of the exchanger and reducing the need for maintenance.

- Applications Across Industries: The use of nanomaterials in heat exchangers is not limited to a single sector. Industries ranging from power generation, HVAC, automotive, and even electronics cooling benefit from the advancements in nanomaterial technology, allowing for more efficient, reliable, and eco-friendly heat management solutions.

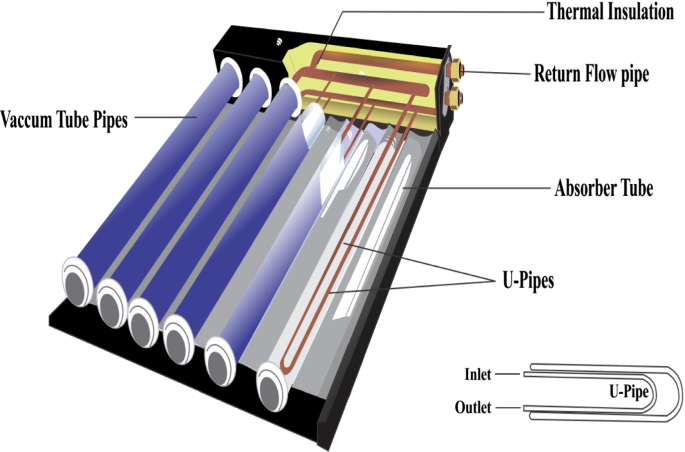

- Potential for Renewable Energy Systems: Nanomaterial-enhanced heat exchangers hold great potential in renewable energy systems such as solar thermal collectors, geothermal systems, and waste heat recovery, where high-efficiency heat transfer is essential for maximizing energy output.

- Tailored Thermal Properties: Nanomaterials can be engineered to have specific thermal properties based on the needs of the application. For example, the size, shape, and composition of nanoparticles can be adjusted to optimize heat transfer characteristics for different industries, such as microelectronics cooling or large-scale industrial processes.

- Hybrid Nanocomposites: By combining different types of nanomaterials into hybrid nanocomposites, heat exchangers can achieve even greater thermal conductivity. These materials blend the unique properties of different nanoparticles (e.g., metal oxides and carbon-based materials) to create synergistic effects, improving both heat transfer efficiency and mechanical strength.

- Improved Phase Change Materials (PCMs): Nanomaterials can be incorporated into phase change materials used in heat exchangers, enhancing the heat absorption and release processes. This leads to faster and more efficient energy storage and retrieval, which is particularly useful in thermal energy storage systems.

- Enhanced Surface Area-to-Volume Ratios: The small size of nanomaterials significantly increases the surface area-to-volume ratio, which is crucial for heat exchange. This larger surface area allows for more effective contact between the working fluids and the exchanger surfaces, boosting overall heat transfer rates.

- Reduction of Boundary Layer Resistance: Nanomaterials can help reduce boundary layer resistance (thermal resistance at the solid-fluid interface), thereby promoting smoother heat transfer between the exchanger walls and the fluids. This improvement reduces heat loss and enhances the overall efficiency of the heat exchanger system.

- Self-Cleaning and Anti-Fouling Properties: Some nanomaterials exhibit self-cleaning or anti-fouling characteristics, which can significantly reduce the buildup of scale, biological growth, or dirt on the heat exchanger surfaces. This reduces the frequency of maintenance and improves long-term operational efficiency.

- Thermal Interface Materials (TIMs): Nanomaterials can also be used to enhance thermal interface materials (TIMs) in heat exchangers. These TIMs help reduce thermal resistance at the interface between the heat exchanger components, ensuring that heat transfer between different layers is maximized.

- Nanostructured Coatings for Corrosion Protection: Advanced nanostructured coatings can provide exceptional protection against corrosion and chemical reactions in harsh environments. This increases the longevity of heat exchangers, especially in industries dealing with corrosive fluids, such as chemical processing or seawater applications.

- Rapid Prototyping with Nanomaterials: The use of 3D printing and additive manufacturing technologies with nanomaterial-infused inks allows for the rapid prototyping and customization of heat exchangers with optimized thermal performance, making it easier to develop highly specialized designs for niche applications.