Water-Energy Nexus

Introduction

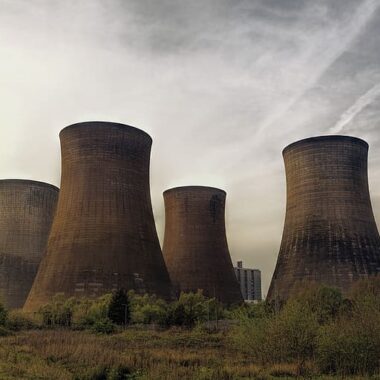

Water-Energy Nexus refers to the intricate relationship between water and energy resources, highlighting how the consumption and management of one significantly impacts the other. As populations grow and demand for resources increases, understanding this nexus becomes critical for sustainable development. Water is essential for energy production—power plants rely on substantial amounts of water for cooling, steam generation, and fuel extraction, while energy is required for the extraction, treatment, and distribution of water.

This interdependency raises significant challenges, especially in regions facing water scarcity or energy shortages. Efficient management of both resources is vital to ensure sustainability, particularly in industries such as cooling systems, where cooling towers consume considerable amounts of water and energy.

Key Aspects of the Water-Energy Nexus in Cooling Towers

- Water Consumption: Cooling towers use large volumes of water for cooling purposes, which can strain local water resources, especially in arid regions. The evaporation process in cooling towers leads to significant water loss, making it essential to consider water availability when designing and operating these systems.

- Energy Use: The operation of cooling towers requires energy, primarily for pumps, fans, and other auxiliary equipment. Energy-efficient designs and technologies can reduce the overall energy consumption of cooling systems, directly impacting the operational costs and environmental footprint.

- Evaporative Cooling Efficiency: The efficiency of cooling towers is often measured by their ability to maximize heat rejection while minimizing water consumption. By optimizing design parameters, such as airflow and water distribution, facilities can enhance cooling efficiency and reduce water use.

- Recycling and Reusing Water: Implementing water recycling systems within cooling towers can significantly mitigate water consumption. Techniques such as blowdown recovery, where excess water is treated and reused, help balance the water-energy equation by conserving water resources and reducing the need for freshwater intake.

- Advanced Technologies: Innovations in cooling tower technology, such as hybrid cooling systems, can improve water and energy efficiency. Hybrid systems utilize both evaporative and dry cooling methods, allowing facilities to adjust cooling strategies based on environmental conditions and operational demands.

- Regulatory Considerations: Increasing regulations surrounding water usage and energy efficiency are influencing the design and operation of cooling towers. Compliance with environmental standards encourages industries to adopt more sustainable practices, such as reducing water consumption and optimizing energy use.

- Climate Impact: Climate change exacerbates the water-energy nexus by altering precipitation patterns and increasing temperatures. As water availability fluctuates, cooling tower operators must adapt their strategies to maintain efficient operations without overexploiting water resources.

- Performance Monitoring: Implementing advanced monitoring systems allows for real-time tracking of water and energy usage in cooling towers. Data analytics can help identify inefficiencies, enabling timely interventions and informed decision-making to optimize resource use.

- Life Cycle Assessment: Evaluating the life cycle of cooling tower systems can provide insights into their overall environmental impact. By considering water and energy inputs throughout the lifecycle, industries can identify opportunities for resource optimization and sustainability.

- Stakeholder Collaboration: Addressing the water-energy nexus requires collaboration among stakeholders, including facility managers, engineers, regulatory bodies, and local communities. Engaging in dialogues and sharing best practices can lead to innovative solutions that balance resource use and efficiency.

- System Optimization: By employing advanced control systems and automation, cooling towers can optimize their operation based on real-time weather conditions, system load, and water availability. This adaptability helps maximize cooling efficiency while minimizing water and energy use.

- Water Quality Management: Maintaining proper water quality is vital for cooling tower performance. Implementing effective water treatment solutions can reduce the risk of fouling, scaling, and corrosion, thereby enhancing operational efficiency and extending equipment lifespan. Improved water quality can also lead to reduced water usage by minimizing blowdown rates.

- Impact of Technology Upgrades: Upgrading to more energy-efficient pumps and fans can significantly reduce the energy demand of cooling towers. Variable speed drives (VSDs) allow for precise control over water and airflow, ensuring that energy consumption aligns with cooling requirements.

- Alternative Cooling Methods: Exploring alternative cooling technologies, such as dry cooling and hybrid systems, can mitigate the reliance on water. These methods use less water, especially in cooler climates, helping to conserve this critical resource while still maintaining effective cooling performance.

- Public Awareness and Education: Raising awareness about the water-energy nexus among facility managers, operators, and the general public can promote better practices in cooling tower management. Educational programs can emphasize the importance of water conservation and energy efficiency, fostering a culture of sustainability.

Conclusion

The relationship between cooling towers, water usage, and energy consumption highlights the need for a balanced approach to resource management. By implementing strategies that enhance efficiency, promote sustainability, and engage stakeholders, industries can optimize their cooling processes while safeguarding vital water and energy resources. As the challenges of climate change and resource scarcity intensify, prioritizing the water-energy nexus will be essential for achieving sustainable operational goals in the cooling sector.