Thermal Load Capacity

Introduction

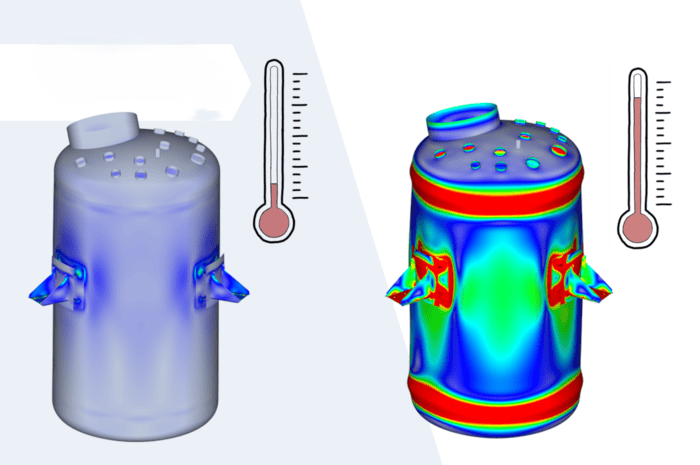

Thermal load capacity is a critical parameter in engineering and design, defining the maximum amount of heat that a system, material, or device can efficiently manage without compromising its functionality, safety, or structural integrity. This concept is integral across various industries, such as HVAC, power generation, electronics, manufacturing, and renewable energy, where managing heat is essential to maintain performance and extend operational lifespan. With the rapid advancements in technology and the increasing complexity of systems, understanding and optimizing thermal load capacity has become a cornerstone of innovation, enabling engineers to develop solutions that can handle higher heat loads while ensuring energy efficiency and environmental sustainability.

Whether it involves cooling high-performance electronic devices, optimizing industrial processes, or managing heat in renewable energy systems, thermal load capacity underscores the balance between heat generation and dissipation. It demands a multidisciplinary approach, integrating material science, fluid dynamics, and thermal engineering, to create robust and efficient solutions for the challenges of modern applications.

Key Factors Affecting Thermal Load Capacity (Elaborated)

- Material Properties

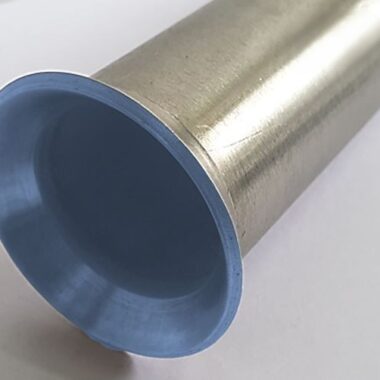

- Materials with high thermal conductivity, such as copper, aluminum, and silver, can transfer heat efficiently, making them suitable for applications like heat exchangers and cooling systems.

- Specific heat capacity determines how much heat a material can store per unit mass, playing a critical role in thermal buffering in transient systems.

- Thermal expansion must be considered to avoid mechanical stress or failure when materials experience temperature changes, especially in composite structures or extreme environments.

- Cooling Mechanisms

- Air Cooling: Uses fans or natural convection to dissipate heat. Ideal for systems with moderate heat loads.

- Liquid Cooling: Incorporates water, oils, or coolants for more efficient heat transfer, widely used in industrial applications and high-performance computing.

- Phase-Change Cooling: Involves evaporation and condensation processes, as seen in refrigeration systems or heat pipes, offering highly efficient heat dissipation.

- Emerging techniques such as direct immersion cooling, where components are submerged in a non-conductive cooling liquid, are gaining attention for high-capacity thermal management.

- Surface Area

- Increasing the surface area available for heat exchange, such as through fins, corrugated surfaces, or porous materials, enhances thermal dissipation.

- Advanced manufacturing methods, like 3D printing, enable the creation of complex heat-dissipating geometries optimized for specific applications.

- Environmental Conditions

- Ambient Temperature: Affects the thermal gradient between the system and its surroundings, directly influencing the rate of heat dissipation.

- Airflow and Humidity: Systems in environments with high airflow benefit from enhanced convection, while high humidity may affect cooling performance, especially in air-based systems.

- Altitude: At higher altitudes, reduced air density decreases cooling efficiency, necessitating design adjustments.

- Operational Load

- Systems operating under continuous or peak loads generate more heat, requiring higher thermal load capacities to maintain functionality.

- Transient or variable load systems benefit from dynamic thermal management solutions, such as adaptive cooling algorithms or phase-change materials for buffering heat spikes.

- Thermal Insulation

- Proper insulation prevents unwanted heat transfer, ensuring energy efficiency in heating or cooling systems.

- Innovations in aerogel insulation and phase-change materials provide superior thermal resistance and energy storage capabilities.

Future Directions and Innovations in Thermal Load Capacity

- Advanced Materials:

- Graphene-Based Materials: Offering unparalleled thermal conductivity, graphene composites are paving the way for high-performance cooling in electronics and aerospace applications.

- Metallic Foams: Lightweight structures with high thermal conductivity and surface area are being developed for advanced heat dissipation.

- Smart Thermal Management Systems:

- AI-Driven Cooling: Algorithms monitor and predict heat loads, dynamically adjusting cooling mechanisms for optimal performance.

- Thermal Sensors and IoT Integration: Real-time monitoring of thermal parameters ensures proactive maintenance and energy-efficient operation.

- Additive Manufacturing:

- Custom designs for heat exchangers and cooling systems are possible with 3D printing, enabling precise control over heat dissipation pathways and structures.

- Renewable Energy Systems:

- Thermal load management in solar power plants and wind turbines ensures efficient operation under varying environmental conditions.

- Thermal Energy Storage systems, using molten salts or phase-change materials, are revolutionizing energy storage and grid stability.

- Nanotechnology in Heat Management:

- Nanofluids: Engineered fluids with suspended nanoparticles enhance thermal conductivity and heat transfer in cooling systems.

- Nano-coatings: Applied to surfaces to improve heat transfer rates and corrosion resistance.

- Eco-Friendly Cooling Solutions:

- Use of environmentally friendly refrigerants and natural coolants is becoming a priority to reduce the carbon footprint of cooling systems.

- Innovations in solid-state cooling, like thermoelectric devices, eliminate the need for refrigerants altogether.