Direct Contact Heat Rejection

Introduction

Direct Contact Heat Rejection (DCHR) is an innovative and efficient cooling technology that has gained widespread adoption across various industrial applications. Unlike conventional heat rejection methods that rely on heat exchangers to transfer heat between two fluids without mixing them, DCHR involves the direct interaction of the hot fluid and the cooling medium. This direct mixing facilitates more effective heat transfer, significantly enhancing the overall cooling performance. In DCHR systems, the hot fluid, such as steam or process fluid, comes into contact with a cooler medium like water or air, allowing for the rapid dissipation of thermal energy. This approach eliminates the need for complex heat exchangers, making the design and operation of cooling systems more streamlined and cost-effective. DCHR is particularly useful in large-scale applications such as power generation, chemical processing, desalination plants, and HVAC systems, where efficient and reliable cooling is crucial to maintaining operational performance. The primary advantage of DCHR lies in its simplicity, efficiency, and suitability for managing high heat loads in diverse industrial processes.

Key Features of Direct Contact Heat Rejection:

-

Direct Fluid Interaction:

- How it Works: In DCHR, the hot fluid (often steam, process fluids, or other high-temperature liquids) comes directly into contact with the cooling medium, which is typically water or air. This enables the thermal energy in the hot fluid to transfer directly to the cooler medium, allowing the fluid to cool down efficiently.

- Why It’s Important: By eliminating the barrier between the two fluids, DCHR maximizes the contact surface area, facilitating rapid heat dissipation. The absence of a heat exchanger significantly improves the speed and effectiveness of the cooling process.

-

No Heat Exchanger Needed:

- How it Works: In traditional cooling methods, heat exchangers are used to transfer heat between two fluids that do not mix. In contrast, DCHR allows the hot and cooling fluids to mix directly, thus bypassing the need for a physical heat exchanger.

- Why It’s Important: This direct contact mechanism simplifies the system design, eliminating the cost and complexity of installing heat exchangers. It also reduces maintenance requirements since there are no components like heat exchanger tubes that can suffer from fouling or wear.

-

High Efficiency:

- How it Works: DCHR’s direct contact method enhances the heat transfer efficiency by allowing the maximum possible thermal exchange between the fluids. The thermal boundary layer between the two fluids is minimized, which increases the rate of heat dissipation.

- Why It’s Important: This efficiency allows DCHR systems to achieve better cooling performance with less energy input. The reduced need for mechanical systems or energy-intensive components can also contribute to energy savings, making it a more sustainable solution.

-

Simpler Design:

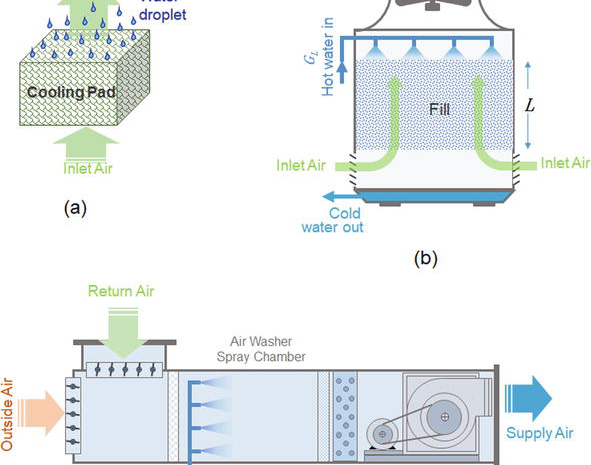

- How it Works: Without the need for complex heat exchangers, pumps, or piping systems, DCHR setups are generally simpler and more compact in design. Cooling towers or spray systems are often used to facilitate this type of heat rejection.

- Why It’s Important: A simpler design results in lower upfront costs and less complex installation processes. Moreover, it makes the system easier to operate, maintain, and repair over time.

-

Suitable for Large-Scale Applications:

- How it Works: DCHR is widely used in large industries and power plants that handle vast amounts of heat and require efficient cooling mechanisms. These systems can handle large quantities of heat with minimal complexity, making them ideal for large-scale operations.

- Why It’s Important: The ability to manage large heat loads while maintaining high efficiency makes DCHR an attractive choice for power plants, chemical manufacturing, and other high-demand industries.

Applications of Direct Contact Heat Rejection

-

Power Plants:

- How it Works: In power plants, especially thermal power plants, steam condensers are essential to cool down exhaust steam from turbines. DCHR is used to cool the steam condensers by using water or air, which absorbs the heat from the steam. The steam and water (or air) are directly mixed in cooling towers or spray ponds.

- Why It’s Important: Power plants need to reject large amounts of heat efficiently, and DCHR offers an energy-efficient and effective cooling method for these systems, preventing overloading and improving overall plant performance.

-

Industrial Cooling:

- How it Works: In industries such as chemical processing, petrochemical production, and metal manufacturing, DCHR is applied to cool down process fluids or gases that generate excessive heat during production. Water or cooling towers are often used in direct contact with the heated fluids to reject the thermal energy.

- Why It’s Important: These industries produce high-temperature fluids that need to be cooled before they can be reused or discharged. DCHR provides a cost-effective, reliable, and fast way to bring down the temperature of these fluids, minimizing downtime and increasing efficiency in operations.

-

HVAC Systems:

- How it Works: In large HVAC systems, particularly in commercial and industrial buildings, DCHR can be used to cool large volumes of air or water circulating through cooling coils or other components of the air conditioning system.

- Why It’s Important: Large HVAC systems require efficient heat rejection to ensure that the air is kept at the desired temperature. DCHR enables faster and more efficient cooling, ensuring the system operates efficiently without excessive energy consumption.

-

Desalination Plants:

- How it Works: DCHR is used in desalination plants to cool down brine and other byproducts produced during the desalination process. Water is often used as the cooling medium to absorb the heat directly from the brine or steam.

- Why It’s Important: Desalination plants need efficient cooling mechanisms to manage the high heat generated during the desalination process. DCHR offers an effective and environmentally friendly way to handle this heat without requiring complex cooling systems.

Benefits of Direct Contact Heat Rejection:

-

Improved Heat Transfer Efficiency:

- Why It’s Important: The direct mixing of hot fluid and cooling medium allows heat to be transferred more rapidly than through conventional heat exchangers. This leads to faster cooling, which is essential in applications where maintaining certain temperature levels is crucial for the process.

-

Reduced Equipment Size:

- Why It’s Important: Since DCHR doesn’t require large heat exchangers, pumps, or other components, the overall equipment size is minimized. This reduces the footprint of cooling systems, which can be a significant advantage in space-constrained environments, such as industrial plants or data centers.

-

Lower Operating Costs:

- Why It’s Important: DCHR systems require fewer components and less energy to operate, leading to reduced electricity consumption and fewer operational expenses. Additionally, the simplified design lowers both installation and maintenance costs, making it a more cost-effective long-term solution.

-

Environmental Benefits:

- Why It’s Important: DCHR can use natural water bodies (like rivers, lakes, or the sea) as cooling mediums, significantly reducing the environmental impact associated with cooling systems. Moreover, the efficiency of DCHR leads to lower energy consumption, contributing to a reduction in the carbon footprint.

Conclusion

Direct Contact Heat Rejection (DCHR) presents a highly effective and energy-efficient solution for cooling large volumes of hot fluids in industrial applications. By allowing direct interaction between the hot fluid and the cooling medium, DCHR systems are able to achieve faster and more efficient heat transfer, reducing the need for complex heat exchangers and lowering the overall cost and maintenance requirements. DCHR is increasingly being implemented in industries such as power generation, chemical manufacturing, HVAC, and desalination due to its ability to handle large heat loads with minimal complexity. The benefits of DCHR are not only limited to improved heat transfer efficiency but also include reduced equipment size, lower operational costs, and a more sustainable approach to cooling. As industries continue to focus on energy conservation and environmental responsibility, DCHR stands as a key technology that meets the demands for cost-effective, high-performance cooling solutions while minimizing environmental impact. With its many advantages, DCHR is set to play an integral role in the future of industrial cooling technologies.