Advancements in Plate Heat Exchanger Technology

Advancements in Plate Heat Exchanger Technology

Plate heat exchangers (PHEs) have long been esteemed for their effective heat transfer capabilities, compact estimate, and versatility. Later innovative progressions have encourage upgraded their execution, reliability, and application run. Here are a few outstanding progressions and advancements in plate heat exchanger technology :

1. Enhanced Plate Design

Cutting edge PHEs include inventive plate plans that altogether improve heat transfer productivity. These plans incorporate:

- Chevron Designs: Optimized chevron points and depths increment turbulence, upgrading heat transfer whereas minimizing pressure drop.

- Asymmetric Plates: Asymmetric plate plans adjust thermal execution with water powered productivity, catering to particular process necessities.

2. Advanced Materials

The advancement of new materials has extended the application extend and durability of PHEs:

- Corrosion-Resistant Combinations: Utilize of combinations like titanium and Hastelloy expands the life of PHEs in aggressive environments, such as seawater cooling and chemical processing.

- Polymer Materials: High-performance polymers give lightweight, corrosion-resistant choices for specific applications.

3. Gasket Developments

Gaskets play a pivotal part within the fixing and upkeep of PHEs. Later advancements include:

- Clip-On Gaskets: These gaskets are less demanding to introduce and replace, decreasing maintenance time and costs.

- Long-Life Gaskets: Advanced materials expand the life expectancy of gaskets, minimizing the require for frequent replacements.

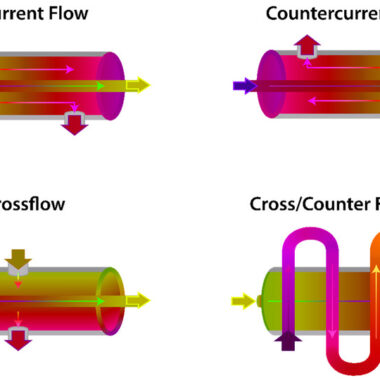

4. Hybrid Heat Exchangers

Hybrid heat exchangers combine the benefits of different heat exchanger sorts:

- Plate and Shell Heat Exchangers: These combine the compactness of plate heat exchangers with the high-pressure taking care of capabilities of shell-and-tube plans, advertising improved execution for demanding applications.

5. Enhanced Cleanability

Improved plans encourage easier cleaning and maintenance:

- Wider Gap Plates: These plates decrease fouling and allow for easier cleaning in applications with particulate-laden liquids.

- Self-Cleaning Plans: Certain progressed PHEs include self-cleaning capabilities, reducing downtime and maintenance costs.

6. Modular Configurations

Measured PHEs offer flexibility and scalability:

- Expandable Designs: Secluded PHEs can be extended by adding more plates, permitting for capacity adjustments without replacing the whole unit.

- Custom Configurations: Measured designs empower customized configurations to meet particular handle requirements.

7. Digitalization and IoT Integration

The integration of advanced technologies improves monitoring and control:

- Smart Sensors: Implanted sensors screen temperature, pressure, and stream rates in real-time, empowering predictive support and execution optimization.

- IoT Connectivity: Internet of Things (IoT) network allows farther checking and control, progressing operational efficiency and reducing the chance of unexpected failures.

8. Energy Efficiency Improvements

Technological advancements have centered on lessening energy utilization:

- Low Pressure Drop Plans: Improved plate plans diminish weight drop, lowering the energy required for liquid pumping.

- Heat Recovery Systems: Integration with heat recovery systems maximizes energy utilization, improving overall prepare proficiency.

9. Compact and Lightweight Designs

Modern materials and manufacturing methods have empowered more compact and lightweight PHEs:

- Space-Saving Solutions: These plans are perfect for applications with constrained space, such as marine and HVAC systems.

- Portable Units: Lightweight, portable PHEs are presently accessible for portable and brief installations.

Conclusion

Advancements in plate heat exchanger innovation have altogether improved their execution, reliability, and flexibility. From innovative plate plans and progressed materials to digitalization and energy productivity enhancements, these advancements are driving the selection of PHEs in a broader extend of industries and applications. By staying abreast of these headways, businesses can use the latest technologies to optimize their thermal processes and progress operational efficiency.