Air Cooled Heat Exchanger Design

AIR COOLED HEAT EXCHANGER DESIGN

In the air-cooled type heat exchanger process fluid is passed through tubes. Tube with fins can be installed in different passes and circulation movements based on the property of process fluid. Air is circulated to accelerate heat transfer. For air circulation forced and induced type of fan can be installed for the process cooler.

The Air-Cooled Heat Exchanger is made of relatively simple materials.

- A finned tube bundle with rectangular box Headers on either end makes up the majority of air-cooled exchangers.

- One or more fans are used to provide cooling air.

- Most of the time, air flows through a horizontal tube bundle upward.

- Depending on whether air is pushed or drawn through the tube bundle, the fans can either be forced or induce draught.

- A plenum chamber that guides the air encloses the area between the fans and the tube bundle. Typically, the entire assembly is supported by legs or a pipe rack.

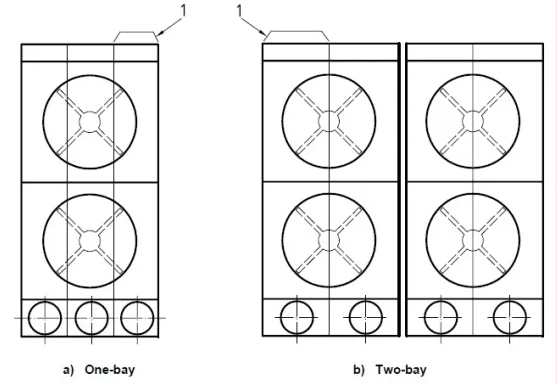

BAY ARRANGEMENTS

A bay is defined as one or more tube bundles that are supported by two or more fans. And along with the structure, plenum, and other supporting components.

TUBE BUNDLE ORIENTATION OF AIR COOLED HEAT EXCHANGER

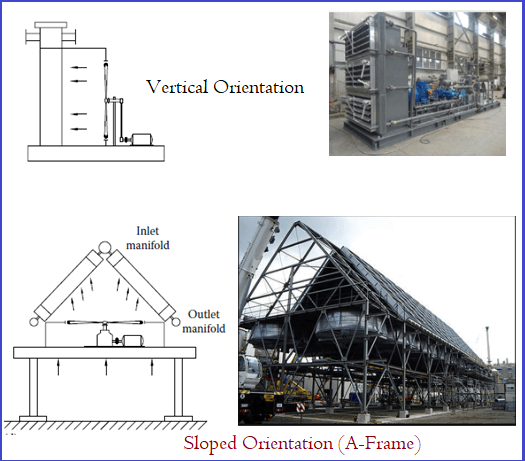

There are three conceivable orientations for an ACHE tube bundle:

- horizontal

- vertical

- sloping.

In process industries, horizontal orientation is the most popular and prevalent form.

Although arranging the tube bundles vertically can save a lot of space. And the performance of the air cooler is heavily reliant on the current wind speed and direction. Therefore, the performance of the air-cooled heat exchanger will be significantly decreased if the predominant wind is in the other direction.

The ground area required and exchanger performance are compromised by A-frame or V-frame air-cooled heat exchanger systems. Two bundles are inclined at 45°-60° and linked at the top or bottom by headers. As a result, it assumes an A or V shape. The A-frame type with forced draught fans is employed in steam condensing applications.

Applications of Dry Cooling Towers - Cool Fab Equipments January 12, 2024 at 6:12 pm

[…] cooling towers, moreover known as air-cooled heat exchangers, discover applications in different businesses where water preservation, natural controls, or […]

The Evolution of Air Cooled Heat Exchangers - Cool Fab Equipments January 12, 2024 at 7:01 pm

[…] and engineers started testing with different blade geometries to upgrade heat exchange. Louvered balances, wavy balances, and other progressed blade plans were presented to optimize […]