Applications of Dry Cooling Towers

Applications of Dry Cooling Towers

Dry cooling towers are fundamental components in different industrial and commercial applications where heat has to be disseminated effectively without the utilize of water. Here are a few key applications of dry cooling towers:

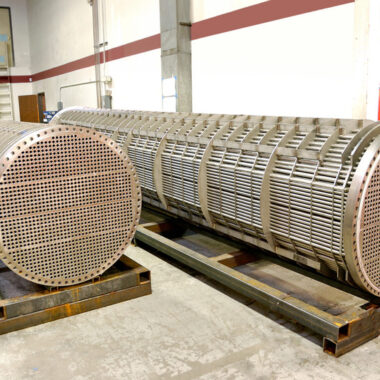

1. Power Generation

a. Thermoelectric Power Plants

Cooling Steam Condensers: Dry cooling towers are utilized to condense steam in control plants, particularly in regions where water is rare.

Progressing Plant Proficiency: By utilizing air to cool the condensers, power plants can work more effectively and economically.

b. Nuclear Power Plants

Secondary Cooling Systems: Dry cooling towers give an additional layer of cooling, decreasing the dependence on water sources and improving security.

2. Industrial Processes

a. Chemical Fabricating

Prepare Cooling: Dry cooling towers help maintain ideal temperatures in chemical responses, guaranteeing item quality and safety.

Dissolvable Recuperation Frameworks: They are utilized in cooling dissolvable recuperation frameworks, where water defilement must be maintained a strategic distance from.

b. Petroleum Refineries

Heat Recovery Systems: Dry cooling towers are utilized to recover heat from different refinery forms, making strides energy proficiency.

Cooling High-temperature Equipment: They give cooling for equipment working at tall temperatures, such as distillation columns and reactors.

c. Food and Beverage Industry

Cold Capacity Facilities: Dry cooling towers help maintain low temperatures in cold storage and refrigeration units.

Prepare Cooling: They are utilized in forms such as pasteurization and fermentation, where precise temperature control is crucial.

3. HVAC Systems

a. Commercial Buildings

Air Conditioning Systems: Dry cooling towers are utilized in huge HVAC systems to disseminate heat from air conditioning units, particularly in ranges with water restrictions.

Energy-efficient Cooling: They contribute to the energy effectiveness of HVAC systems by lessening the stack on air conditioning compressors.

b. Residential Complexes

Centralized Cooling Systems: Dry cooling towers are utilized in centralized cooling systems for large private complexes, giving productive and sustainable cooling.

4. Renewable Energy Ventures

a. Solar Power Plants

Cooling Solar Thermal Systems: Dry cooling towers are utilized to disseminate heat from solar thermal power plants, upgrading their effectiveness and maintainability.

Supporting CSP (Concentrated Solar Power): They give cooling for concentrated solar power systems, diminishing water utilization in arid districts.

b. Geothermal Power Plants

Cooling Geothermal Fluids: Dry cooling towers are utilized to cool geothermal fluids after they have been utilized for power generation, minimizing water utilization.

5. Data Centers

a. Server Cooling

Maintaining Ideal Temperatures: Dry cooling towers are utilized to preserve ideal temperatures in information centers, guaranteeing reliable operation of servers.

Energy-efficient Cooling: They contribute to energy-efficient cooling arrangements, diminishing operational costs and environmental affect.

6. Telecommunications

a. Cooling Organize Equipment

Base Stations and Center points: Dry cooling towers are utilized to cool hardware in telecommunications base stations and organize hubs, ensuring solid execution.

7. Automotive Industry

a. Testing Facilities

Engine Testing: Dry cooling towers are utilized in engine testing facilities to scatter heat from test engines, guaranteeing exact comes about.

Climate Control Chambers: They give cooling for climate control chambers utilized in vehicle testing, maintaining exact environmental conditions.

8. Pharmaceutical Industry

a. Fabricating Forms

Cooling Pharmaceutical Reactors: Dry cooling towers are utilized to cool reactors and other hardware in pharmaceutical manufacturing, guaranteeing item quality and security.

Maintaining Clean Room Conditions: They offer assistance maintain the fundamental temperature and humidity conditions in pharmaceutical clean rooms.

Conclusion

Dry cooling towers are flexible and environmentally inviting cooling arrangements that discover applications over different businesses. Their capacity to dissipate heat without utilizing water makes them especially profitable in districts with water scarcity and in applications where water contamination could be a concern. By integrating dry cooling towers into their systems, businesses can upgrade productivity, diminish environmental impact, and guarantee dependable operation.