Bearings for Cooling Fans

Introduction

Bearings for Cooling fans play a vital role in industrial cooling systems by dissipating excess heat and maintaining process efficiency. However, these fans operate in harsh conditions, including high humidity, extreme temperatures, airborne contaminants, and constant vibration, all of which contribute to premature bearing failure. Traditional bearings often suffer from wear and tear, leading to frequent maintenance, costly repairs, and unplanned downtime. To address these challenges, extended life bearings have been developed specifically for cooling tower fans. These bearings feature advanced materials, specialized coatings, enhanced lubrication, and superior sealing technologies, significantly increasing their lifespan and reliability. By reducing friction, preventing corrosion, and minimizing wear, extended life bearings enhance cooling tower efficiency and overall operational performance. This article explores the importance, benefits, features, and applications of extended life bearings for cooling tower fans, providing insights into how industries can optimize cooling system performance while reducing long-term operational costs.

Key Features of Extended Life Bearings

-

Advanced Lubrication Systems

- Special lubricants designed to handle high moisture levels, extreme temperatures, and heavy loads.

- Reduces friction, minimizes heat generation, and extends the bearing’s operational life.

- Some bearings incorporate solid lubrication or self-lubricating materials to eliminate the need for frequent maintenance.

-

Corrosion-Resistant Materials

- Bearings made from stainless steel, ceramic hybrids, or coated surfaces to resist moisture, chemical exposure, and rust formation.

- Ensures longevity even in environments with constant exposure to water, mist, and airborne pollutants.

-

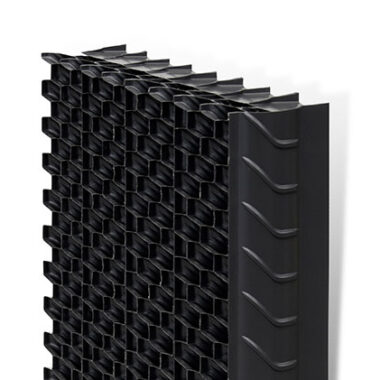

Enhanced Sealing Mechanisms

- Features such as triple-lip seals, labyrinth seals, or shielded designs that prevent dirt, dust, and moisture from penetrating the bearing.

- Protects internal components, reducing wear and improving reliability.

-

High Load-Carrying Capacity

- Engineered to withstand heavy axial and radial loads, ensuring smooth operation under continuous high-speed conditions.

- Reduces the risk of premature bearing failure in demanding cooling tower applications.

-

Self-Aligning Capabilities

- Some extended life bearings feature self-aligning properties, allowing them to accommodate shaft misalignment and vibrations.

- This prevents excessive stress on the bearing and extends its service life.

Benefits of Using Extended Life Bearings in Cooling Tower Fans

-

Longer Service Life

- Extended life bearings last significantly longer than standard bearings due to superior materials and lubrication systems.

- Reduces frequent replacement needs, lowering long-term operational costs.

-

Reduced Maintenance Requirements

- Self-lubricating or enhanced lubricant retention minimizes the need for regular greasing and maintenance checks.

- Less downtime means increased productivity and improved cooling efficiency.

-

Lower Energy Consumption

- By reducing friction and optimizing load distribution, extended life bearings contribute to more efficient fan operation and lower energy usage.

- Helps in reducing overall operational expenses and enhances sustainability.

-

Better Resistance to Harsh Environments

- Designed to withstand extreme conditions such as high humidity, water splashes, airborne contaminants, and fluctuating temperatures.

- Ideal for industries where cooling towers are exposed to chemicals, corrosive gases, or harsh weather.

-

Minimized Risk of Bearing Failure

- Prevents common issues like overheating, excessive wear, and misalignment, which often lead to sudden bearing failures.

- Increases reliability and safety in industrial cooling operations.

Applications of Extended Life Bearings in Cooling Towers

-

HVAC Systems

- Used in commercial and industrial air conditioning and ventilation cooling towers to ensure continuous, energy-efficient operation.

-

Power Plants

- Essential in power generation facilities where cooling towers manage excess heat from turbines and generators.

- Prevents overheating and enhances the overall efficiency of the plant.

-

Petrochemical Industry

- Cooling towers in refineries and chemical processing plants rely on high-performance bearings to operate under corrosive and high-temperature conditions.

-

Manufacturing and Process Industries

- Bearings play a crucial role in maintaining cooling efficiency in steel mills, paper mills, cement plants, and automotive factories.

- Reduces the risk of downtime due to bearing failure in heavy-duty operations.

-

Food and Beverage Industry

- Used in cooling towers for temperature control in breweries, dairy plants, and food processing units.

- Ensures consistent cooling performance while complying with hygiene and safety standards.

-

Aerospace and Automotive

- Cooling towers in wind tunnels, engine testing facilities, and industrial automotive plants require high-efficiency bearings to maintain optimal heat dissipation.

Conclusion

Bearings for cooling fans is a crucial step toward enhancing system reliability, reducing maintenance costs, and improving overall cooling performance. By incorporating high-quality materials, advanced lubrication systems, and superior sealing mechanisms, these bearings offer exceptional durability even in the most challenging environments. With industries increasingly focusing on energy efficiency and operational longevity, extended life bearings provide a cost-effective and reliable solution. By investing in these advanced bearings, businesses can ensure longer service life, minimized downtime, and optimal cooling tower efficiency, leading to higher productivity and significant cost savings in the long run. The integration of extended life bearings in cooling tower fans is a game-changer for industries seeking high efficiency, reliability, and cost savings. By utilizing advanced materials, superior sealing, and optimized lubrication, these bearings drastically reduce maintenance, prevent premature failures, and enhance cooling system performance.