Comparing Air-Cooled vs. Water-Cooled Chiller

Introduction

Chiller are essential components in many industrial and commercial facilities, providing cooling to various processes, equipment, and spaces. When selecting a chiller for your facility, one of the most critical decisions is choosing between an air-cooled chiller and a water-cooled chiller. Both types have distinct advantages and disadvantages, depending on your specific requirements. Here’s a comprehensive comparison to help you determine which type of chiller is right for your facility.

Air Cooled Chillers

Air-cooled chillers use air to remove heat from the refrigerant. The heat is expelled into the atmosphere through a series of fans and coils. These chillers are typically installed outside or in open areas where airflow is abundant.AIR COOLED CHILLER

Advantages of Air Cooled Chillers:

- Simplicity and Ease of Installation: Air-cooled chillers are simpler to install because they don’t require a cooling tower, water pumps, or piping systems. This reduces the complexity of installation and maintenance.

- Lower Initial Cost: Air-cooled chillers generally have a lower upfront cost compared to water-cooled chillers, making them more budget-friendly for facilities with limited capital.

- Less Maintenance: With no water management system involved, air-cooled chillers typically require less maintenance, as there are no concerns about water treatment, scaling, or corrosion.

- Suitable for Water-Scarce Areas: In regions where water availability is limited, air-cooled chillers are an ideal choice because they do not depend on water for cooling.

Disadvantages of Air Cooled Chillers:

- Lower Energy Efficiency: Air-cooled chillers are generally less energy-efficient compared to water-cooled chillers. This is because air has a lower heat transfer capability than water, which results in higher energy consumption to achieve the same cooling effect.

- Noise Levels: The fans in air-cooled chillers can produce significant noise, which may be a concern in noise-sensitive environments.

- Performance in Hot Climates: Air-cooled chillers may struggle to perform efficiently in extremely hot climates, as the ambient air temperature can reduce their cooling capacity.

Water Cooled Chillers

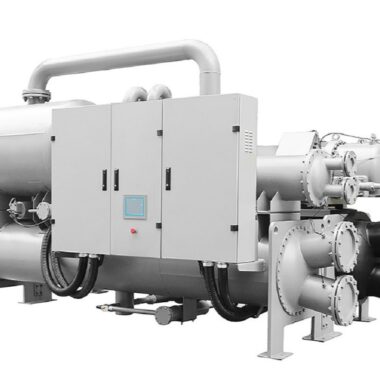

Water-cooled chillers use water to remove heat from the refrigerant. The heat is absorbed by the water, which is then circulated through a cooling tower where the heat is dissipated into the air. Water Cooled Chiller

Advantages of Water Cooled Chillers:

- Higher Energy Efficiency: Water-cooled chillers are generally more energy-efficient than air-cooled chillers, especially in large facilities. Water is a better heat conductor than air, allowing the chiller to achieve more efficient cooling with less energy consumption.

- Longer Lifespan: Water-cooled chillers tend to have a longer operational life compared to air-cooled chillers due to less wear and tear on the equipment. The stable operating environment provided by water cooling leads to better longevity.

- Quieter Operation: Water-cooled chillers typically produce less noise since they do not rely on large air fans. This makes them suitable for environments where noise control is important, such as hospitals, hotels, and office buildings.

Disadvantages of Water Cooled Chillers:

- Higher Initial Cost: Water-cooled chillers generally have a higher upfront cost due to the additional components required, such as cooling towers, water pumps, and extensive piping systems.

- Complex Installation: Installing a water-cooled chiller is more complex, requiring a well-designed water management system. This adds to the time and cost of installation.

- Regular Maintenance Required: Water-cooled chillers require ongoing maintenance, including water treatment to prevent scaling, corrosion, and microbial growth in the cooling tower. Failure to maintain the water system properly can lead to inefficiency and costly repairs.

Factors to Consider When Choosing a Chiller

- Facility Size and Cooling Demand: Large facilities with high cooling demands often benefit from the energy efficiency of water-cooled chillers, while smaller facilities with moderate cooling needs might find air-cooled chillers more practical.

- Climate and Location: For facilities in regions with high ambient temperatures, water-cooled chillers might be a better choice due to their superior performance in hot climates. In contrast, air-cooled chillers are more suited for cooler climates or areas with water scarcity.

- Budget: Consider both the initial investment and long-term operating costs. While air-cooled chillers may have a lower upfront cost, water-cooled chillers often result in lower energy bills over time.

- Maintenance Capabilities: Assess your facility’s capacity for regular maintenance. Water-cooled chillers require more extensive upkeep, so ensure you have the necessary resources for proper maintenance.

- Space Availability: Water-cooled chillers require additional space for cooling towers and water management equipment. If space is limited, an air-cooled chiller might be a more feasible option.

Choosing between an air-cooled and water-cooled chiller depends on your facility’s specific requirements, including cooling needs, location, budget, and maintenance capabilities. Air-cooled chillers are often favored for their simplicity and lower initial costs, especially in smaller facilities or regions where water is scarce. On the other hand, water-cooled chillers provide higher energy efficiency, quieter operation, and better performance in large-scale applications, making them ideal for facilities with significant cooling demands and access to water resources.