Cooling Tower vs Chiller

Introduction

Cooling Tower vs Chiller rely on evaporative cooling, where water is cooled through natural or forced air circulation, making them highly effective in applications requiring bulk cooling, such as power plants, manufacturing units, and HVAC systems. On the other hand, chillers utilize mechanical refrigeration cycles to cool fluids, providing precise temperature control, which is essential for industries like pharmaceuticals, data centers, and medical facilities. The decision to use a cooling tower or a chiller depends on multiple factors, including efficiency, environmental impact, cost, climate adaptability, and maintenance requirements. This comparative study delves into their key differences, advantages, and limitations, helping industries select the optimal cooling solution based on their specific needs. In industrial and commercial cooling applications, cooling towers and chillers are two of the most commonly used heat dissipation systems. While both serve the fundamental purpose of removing excess heat from processes or buildings, they operate on entirely different principles and are suited to different environments and industries.

Cooling Mechanism: How They Work

-

Cooling Tower:

- Uses evaporative cooling, where hot water from an industrial process or HVAC system is sprayed over a fill material inside the tower.

- Air is drawn through the tower, causing some of the water to evaporate, removing heat in the process.

- The cooled water is then recirculated back into the system.

- Efficiency is highly dependent on ambient temperature and humidity levels.

-

Chiller:

- Uses a mechanical refrigeration cycle (either vapor compression or absorption) to cool a liquid, typically water or glycol.

- This chilled liquid is then circulated through a heat exchanger to cool air or process equipment.

- Unlike cooling towers, chillers do not rely on evaporation but instead use refrigerants and compressors to transfer heat.

Key Difference: Cooling towers rely on natural evaporation, whereas chillers use refrigeration cycles to extract heat.

Heat Rejection Process: Where the Heat Goes

-

Cooling Tower:

- Heat is directly rejected into the atmosphere through the process of evaporation.

- The remaining water is cooled down significantly before being recirculated.

- Requires constant water replenishment due to evaporation and drift losses.

-

Chiller:

- Transfers heat to a condenser, which then rejects heat into the air (air-cooled chillers) or water (water-cooled chillers).

- Heat rejection is controlled and independent of environmental factors.

- Water-cooled chillers often require a cooling tower to assist in heat dissipation.

Key Difference: Cooling towers expel heat directly into the air, while chillers transfer heat via a controlled refrigeration process.

Application Suitability: Where They Are Used

-

Cooling Tower:

- Best suited for industrial processes and HVAC applications where large volumes of water need to be cooled efficiently.

- Commonly used in power plants, oil refineries, petrochemical industries, and manufacturing units.

- Preferred in places where water is available and climate conditions allow effective evaporation.

-

Chiller:

- Used in applications that require precise temperature control, such as hospitals, pharmaceuticals, data centers, and food processing.

- Ideal for facilities with limited water availability or those that need to maintain consistent cooling regardless of climate.

Key Difference: Cooling towers handle bulk water cooling, while chillers offer precise and controlled temperature regulation.

Energy Efficiency & Water Consumption

-

Cooling Tower:

- More energy-efficient in cooling large volumes of water since it leverages natural evaporation instead of compressors.

- However, consumes large amounts of water due to evaporation losses, drift, and blowdown.

-

Chiller:

- Requires significant electricity to power compressors, but modern chillers are equipped with variable-speed drives (VSDs) for energy optimization.

- Water-cooled chillers use less water than cooling towers when paired with closed-loop systems.

Key Difference: Cooling towers consume more water but less electricity, while chillers use more electricity but conserve water.

Environmental Impact

-

Cooling Tower:

- Can lead to water wastage and contamination due to chemical treatment and bacterial growth (e.g., Legionella bacteria).

- Generates drift (water droplets carried away by air) that may contain chemicals, affecting air and water quality.

- More eco-friendly than chillers in terms of carbon footprint, as it does not use refrigerants.

-

Chiller:

- Uses refrigerants that may have high Global Warming Potential (GWP), impacting the environment.

- Modern chillers use low-GWP refrigerants to reduce their carbon footprint.

- Water-cooled chillers minimize drift issues, making them cleaner for the environment.

Key Difference: Cooling towers may cause water pollution and drift, while chillers use refrigerants with potential climate impact.

Initial Cost vs. Long-Term Investment

-

Cooling Tower:

- Lower initial cost compared to chillers.

- Requires regular water treatment and maintenance, leading to higher long-term costs.

-

Chiller:

- Higher upfront cost but lower operational maintenance if well maintained.

- Energy savings from high-efficiency models make them cost-effective in the long run.

Key Difference: Cooling towers are cheaper initially but costly in maintenance, whereas chillers are expensive initially but more stable long-term.

Climate Adaptability

-

Cooling Tower:

- Highly effective in hot, dry climates, where evaporation is more efficient.

- Performance declines in humid conditions, as less water can evaporate to remove heat.

-

Chiller:

- Works independently of climate, making it ideal for all regions, including humid or extreme weather conditions.

Key Difference: Cooling towers perform best in dry climates, while chillers work in any environment.

Space Requirements & Installation Flexibility

-

Cooling Tower:

- Requires significant outdoor space and proper placement for airflow.

- Can be noisy due to fan operation.

-

Chiller:

- Can be installed indoors or outdoors depending on the type (air-cooled vs. water-cooled).

- Takes up less space than cooling towers, making it preferable for compact facilities.

Key Difference: Cooling towers need more space, while chillers provide installation flexibility.

Maintenance Complexity & Reliability

-

Cooling Tower:

- Requires frequent water treatment to prevent scaling, corrosion, and bacterial growth.

- Needs drift eliminators and blowdown control to manage water loss.

-

Chiller:

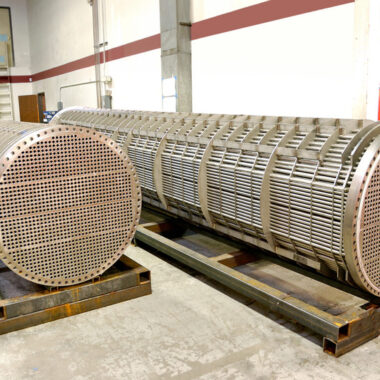

- Requires periodic servicing of compressors, refrigerants, and heat exchangers.

- Less prone to bacterial contamination than cooling towers.

Key Difference: Cooling towers require frequent maintenance, while chillers need technical servicing but are easier to maintain.

Noise Levels & Workplace Comfort on Cooling Tower vs Chiller

-

Cooling Tower:

- Generates high noise levels due to large fans and water splashing.

- Can be a concern in urban areas and workplaces that require a quiet environment.

-

Chiller:

- Air-cooled chillers can be noisy due to fans and compressors, but water-cooled chillers are much quieter.

- More suitable for noise-sensitive environments like hospitals and offices.

Key Difference: Cooling towers are noisier, while chillers offer quieter operation, especially water-cooled models.

Conclusion

Cooling Tower vs Chiller requires a careful evaluation of cooling demands, budget, climate conditions, and long-term sustainability. Cooling towers are cost-effective for large-scale cooling applications, leveraging natural evaporation to dissipate heat, but they require high water consumption and regular maintenance. Chillers, on the other hand, offer precise and consistent cooling in all climate conditions but can be energy-intensive and expensive upfront. For industries requiring bulk water cooling with lower energy costs, cooling towers remain a preferred choice. Meanwhile, facilities that demand precise temperature control, water conservation, and year-round efficiency are better suited for chillers. In some cases, a hybrid approach that combines both systems can enhance efficiency and sustainability by leveraging the strengths of each. Ultimately, the best solution depends on the specific cooling needs of the industry, cost considerations, environmental impact, and operational constraints. With ongoing advancements in energy-efficient cooling technologies, businesses can explore options that optimize both performance and sustainability for long-term success.