Custom Engineered Heat Exchangers

Introduction

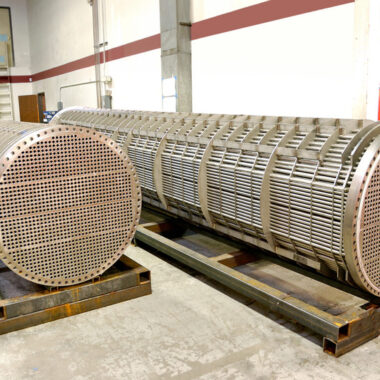

Custom-engineered heat exchangers are designed, manufactured, and optimized based on specific application needs, ensuring maximum performance, durability, and adaptability. They are tailored to handle high-pressure environments, extreme temperature differentials, corrosive fluids, space limitations, and unique flow characteristics. Industries such as power plants, chemical processing, oil and gas, HVAC, marine, food processing, and renewable energy heavily rely on these specialized solutions to maintain operational efficiency. By integrating advanced materials, innovative designs, and cutting-edge fabrication technologies, custom heat exchangers enhance heat transfer efficiency, reduce energy losses, and improve overall system reliability. These specialized units often feature enhanced surface geometries, multi-pass flow arrangements, high-efficiency fins, or turbulence-promoting structures, ensuring they perform optimally under challenging conditions. With the increasing demand for energy efficiency, sustainability, and high-performance cooling systems, custom-engineered heat exchangers are rapidly becoming the preferred choice for industries aiming to optimize heat transfer, minimize environmental impact, and lower long-term operational costs. As we move toward next-generation thermal solutions, the role of custom-engineered heat exchangers will only become more vital in industrial innovation and technological advancement.

Key Features

-

Precision-Tailored Design – Custom heat exchangers are designed to match specific operational needs, ensuring maximum heat transfer efficiency. Engineers analyze factors like fluid type, pressure, temperature range, and space constraints to develop a solution that optimally integrates with the system.

-

High-Performance Materials – Depending on the application’s demands, these heat exchangers can be fabricated using stainless steel, titanium, copper-nickel alloys, carbon steel, or advanced composite materials. This ensures superior corrosion resistance, thermal conductivity, and longevity, even in harsh industrial environments.

-

Enhanced Thermal Efficiency – Custom designs incorporate optimized tube configurations, fin enhancements, and flow patterns to maximize heat transfer while minimizing pressure drops. Multi-pass flow arrangements and turbulent flow designs improve energy efficiency, reducing operational costs.

-

Compact & Space-Saving Construction – In industries where space constraints are critical, such as marine and aerospace applications, custom-engineered heat exchangers are designed with compact geometries, ensuring high performance without compromising system layout.

-

Easy Maintenance & Long Service Life – Custom heat exchangers often include removable tube bundles, self-cleaning mechanisms, and anti-fouling coatings, allowing for easy maintenance, quick inspections, and reduced downtime. These features significantly enhance their lifespan and operational reliability.

Unique Points

-

Designed for Industry-Specific Applications – Unlike off-the-shelf models, custom heat exchangers are built to precisely match the operational challenges of industries like power plants, pharmaceuticals, and HVAC systems, ensuring seamless integration and superior performance.

-

Hybrid Heat Transfer Technologies – Some designs combine conduction, convection, and phase change cooling techniques to achieve the highest possible heat dissipation rates. Microchannel technology, vortex flow designs, and phase change materials (PCM) are integrated for enhanced efficiency.

-

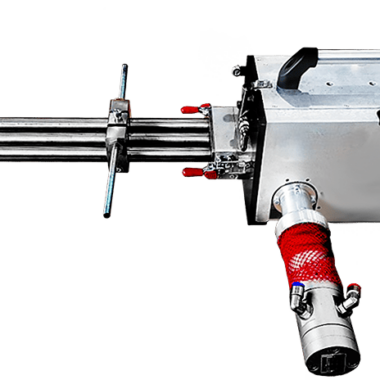

Smart Monitoring & IoT Integration – Next-generation custom heat exchangers incorporate IoT-enabled sensors that monitor temperature, pressure, and flow rates in real-time, providing predictive maintenance alerts to prevent system failures.

-

Multi-Fluid & Multi-Phase Capabilities – Custom designs can handle liquid-to-liquid, gas-to-liquid, or multi-phase heat exchange, making them suitable for complex industrial applications such as hydrocarbon processing, refrigeration, and chemical distillation.

-

Extreme Durability for Harsh Environments – Designed for industries requiring high-pressure, high-temperature, or cryogenic applications, these heat exchangers can withstand corrosive fluids, thermal cycling, and mechanical stress, ensuring long-term reliability.

Future Trends & Innovations

-

3D-Printed Heat Exchangers – Additive manufacturing allows for highly complex and efficient heat exchanger geometries, reducing weight and enhancing heat dissipation. This is particularly useful in aerospace, medical devices, and compact electronic cooling systems.

-

Advanced Nano-Coatings – The use of self-cleaning and anti-corrosion coatings significantly reduces scaling, fouling, and maintenance costs, making heat exchangers last longer in marine and chemical industries.

-

AI-Optimized Thermal Designs – Machine learning algorithms and Computational Fluid Dynamics (CFD) simulations are being used to design ultra-efficient flow paths, leading to improved thermal efficiency and reduced energy consumption.

-

Integration with Renewable Energy Systems – Custom heat exchangers are now being developed to enhance geothermal energy extraction, improve solar thermal efficiency, and optimize waste heat recovery in industrial setups.

-

Modular & Scalable Configurations – Future heat exchangers will have plug-and-play modularity, allowing industries to scale their cooling capacity based on demand, rather than investing in entirely new systems.

Conclusion

Custom-engineered heat exchangers continues to grow. Unlike standard units, customized heat exchangers offer unparalleled flexibility, efficiency, and durability, making them ideal for applications requiring precise temperature control, extreme environmental resistance, and long-term reliability. Advancements in 3D printing, artificial intelligence, computational fluid dynamics (CFD), and smart monitoring systems are transforming the heat exchanger industry. Future innovations will enable ultra-efficient, lightweight, and self-optimizing designs, reducing maintenance costs and environmental impact. With the rise of renewable energy, sustainable manufacturing, and digitalized industrial processes, custom-engineered heat exchangers will play a pivotal role in enhancing energy recovery, optimizing cooling processes, and supporting the global shift toward green technologies. Investing in custom-engineered solutions is no longer a luxury but a necessity for industries aiming to improve performance, extend equipment lifespan, and remain competitive. As technology progresses, these specialized heat exchangers will continue to push the boundaries of efficiency and innovation, shaping the future of industrial heat transfer systems.