Different Types Of Chillers

Different types of Chillers

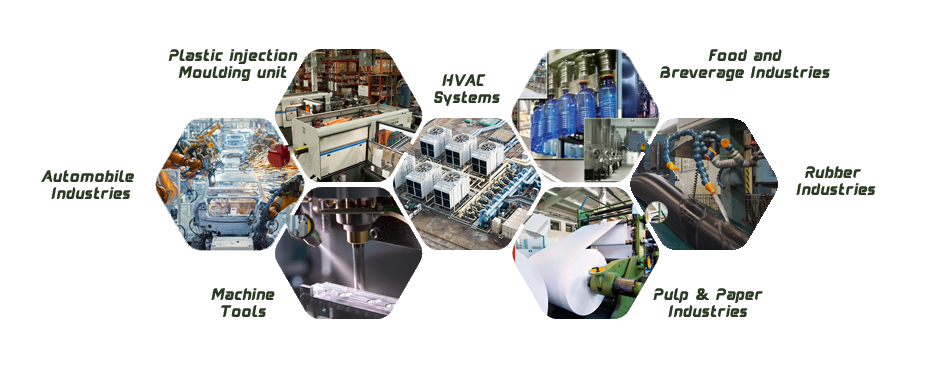

A chiller is a device that removes heat from a liquid through vapor compression, absorption refrigeration cycles, or other thermodynamic cycles. They are commonly used in a variety of applications such as air conditioning, industrial processes, and HVAC systems. There are many different types of chillers, each with its own characteristics and suitable uses. Here are some of the common chillers:

1. Water Cooled Chiller:

Chillers can be classified based on the type of condenser. Because water-cooled chillers use water as the condensing medium, they typically require a cooling tower or water source to remove the heat. Water-cooled chillers operate more efficiently than air-cooled chillers because water transfers heat more efficiently than air.

2. Air Cooled Chiller:

Air-cooled chillers use the surrounding air to dissipate heat. They are suitable for applications where water availability and water quality play an important role. These cooling devices often have fans to dissipate heat. Air-cooled chillers generally have lower maintenance costs.

3. Scroll Chiller:

Scroll chillers use scroll compressors, which are more efficient and quieter than reciprocating compressors. These are commonly used in small to medium sized air conditioning and industrial applications. Scroll chillers can deliver more cold air per unit of energy than other chiller systems, making them a highly efficient option.

4. Screw Chiller:

Screw chillers use a screw compressor to compress the refrigerant. They are suitable for medium to large scale applications and offer excellent energy efficiency and reliability. Screw compressors are most commonly used in industrial processes and petrochemical applications.

5. Glycol Chiller:

The industrial glycol chiller is equipped with a reliable digital temperature controller. This controller allows you to maintain the ideal temperature for your food and drinks.

6. Centrifugal Chiller:

Centrifugal chillers use centrifugal compressors to compress refrigerant. They are often used in large-scale applications where high cooling capacity is required, such as industrial processes or large commercial buildings.

7. Absorption Chiller:

Absorption chillers use a heat source (usually steam or hot water) to power the refrigeration cycle instead of a mechanical compressor. They are suitable for applications where waste heat is readily available, such as industrial processes and combined heat and power (CHP) systems.

8. Portable Chiller:

Portable chillers are compact, self-contained units that are easy to move. Suitable for temporary cooling needs or applications where flexibility is important.

9. Modular Chiller:

Modular chillers consist of several small units that can be combined to achieve the required cooling capacity. Scalability and redundancy make it suitable for applications with varying loads.

The choice of cooler type depends on factors such as cooling capacity requirements, energy efficiency goals, available heat sources, space limitations, and specific application requirements. It is important to carefully consider these factors when selecting the appropriate cooler for a particular application from among the various types of coolers.

Different Types Of Chillers