Explain the Fundamental Concept of Heat Exchangers

Explain the Fundamental Concept of Heat Exchangers

Heat exchangers are devices designed to transfer heat between two or more fluids (liquids, gases, or both) without mixing them. They are fundamental components in many industrial processes, heating and cooling systems, and various engineering applications. The primary purpose of a heat exchanger is to efficiently manage thermal energy transfer to achieve desired temperature changes in the fluids involved. Here let’s explain the fundamental concept of heat exchangers :

Here’s a detailed look at the fundamental concepts of heat exchangers:

Basic Principle

The core principle behind heat exchangers is the transfer of heat from a hotter fluid to a cooler fluid through a solid barrier that prevents the fluids from mixing. This barrier can be a wall or a series of plates, tubes, or other structures that facilitate efficient heat transfer. The main goal is to maximize the heat transfer rate while minimizing energy losses and maintaining the physical separation of the fluids.

Key Components

Heat Transfer Surface:

The surface area where the actual heat exchange takes place. This can be in the form of plates, tubes, or fins, depending on the type of heat exchanger.

Fluids:

Two or more fluids are involved in the heat exchange process. One fluid releases heat (hot fluid), and the other absorbs heat (cold fluid).

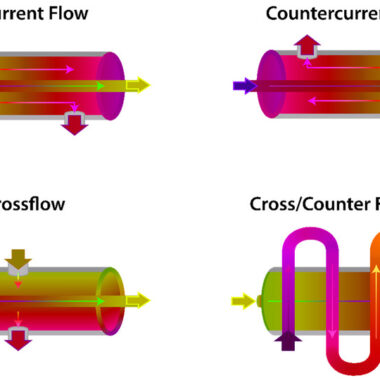

Flow Arrangement:

The manner in which fluids flow relative to each other affects the efficiency and effectiveness of the heat transfer. Common flow arrangements include parallel flow, counterflow, and crossflow.

Types of Heat Exchangers

Plate Heat Exchangers (PHEs):

Consist of a series of thin, corrugated plates stacked together, creating channels for the fluids to flow through. They are compact and efficient, making them ideal for applications where space is limited and high thermal performance is required.

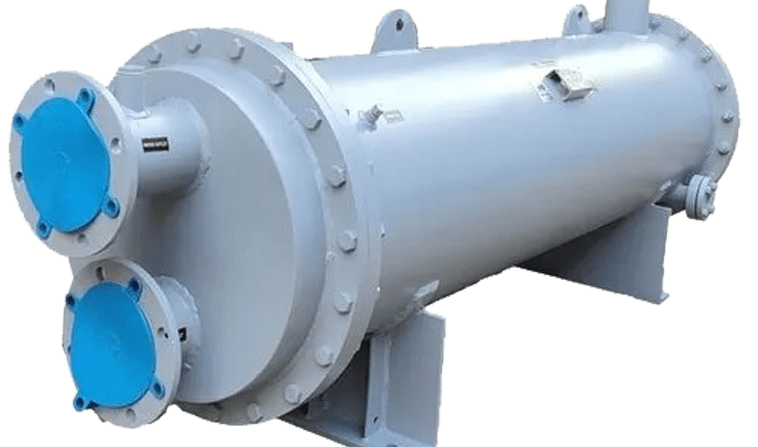

Shell and Tube Heat Exchangers:

Composed of a series of tubes enclosed within a cylindrical shell. One fluid flows through the tubes, while the other fluid flows over the tubes within the shell. They are commonly used in industrial processes and power plants.

Air-Cooled Heat Exchangers:

Use air as the cooling medium instead of water. They consist of finned tubes and are typically used in environments where water is scarce or where air cooling is more economical.

Double Pipe Heat Exchangers:

Consist of one pipe inside another. The hot fluid flows through the inner pipe, while the cold fluid flows through the annular space between the two pipes. This simple design is used for small-scale applications.

Regenerative Heat Exchangers:

Temporarily store heat from the hot fluid in a thermal storage medium and then transfer it to the cold fluid. They are used in applications requiring high-temperature heat recovery.

Heat Transfer Mechanisms

Conduction:

Heat transfer through a solid material, such as the wall or plates of the heat exchanger. The rate of conduction depends on the material’s thermal conductivity.

Convection:

Heat transfer between a solid surface and a fluid. It involves the movement of fluid particles, which enhances the transfer of heat. Convection can be natural or forced, depending on whether fluid motion is driven by buoyancy forces or external means like pumps or fans.

Radiation:

Heat transfer through electromagnetic waves. While radiation is less significant in most heat exchanger applications, it can be relevant in high-temperature environments.

Performance Metrics

Heat Transfer Coefficient (U):

A measure of the heat transfer rate per unit area per unit temperature difference. It depends on the properties of the fluids, the nature of the flow, and the characteristics of the heat transfer surfaces.

Effectiveness (ε):

The ratio of the actual heat transfer to the maximum possible heat transfer. It indicates how well the heat exchanger performs relative to its theoretical maximum.

Pressure Drop:

The reduction in fluid pressure as it flows through the heat exchanger. Minimizing pressure drop is important for maintaining efficient fluid flow and reducing energy consumption.

Thermal Capacity:

The amount of heat the heat exchanger can transfer per unit time. It is a critical parameter in designing and selecting a heat exchanger for specific applications.

Applications

HVAC Systems: For heating and cooling air in buildings.

Industrial Processes: For transferring heat between process fluids in chemical, petrochemical, and food processing industries.

Power Plants: For steam generation, waste heat recovery, and cooling systems.

Automotive: For engine cooling, oil cooling, and air conditioning.

Renewable Energy: For heat recovery in solar thermal systems and geothermal heating.

Conclusion

Heat exchangers are vital components in a wide array of applications, providing efficient thermal management by transferring heat between fluids without mixing them. Understanding the fundamental concepts, including the types, mechanisms of heat transfer, and performance metrics, is essential for selecting and designing heat exchangers to meet specific requirements in various industries.

Share best practices for maintaining Heat Exchangers - Cool Fab Equipments July 15, 2024 at 9:36 pm

[…] Share best practices for maintaining Heat Exchangers : Appropriate maintenance of heat exchangers is crucial to guarantee their productive operation, life span, and security. Underneath are a few best practices to take after for maintaining heat exchangers: […]