Fill Pack Replacement

Introduction

Fill Pack Replacement is a critical aspect of maintaining and optimizing the performance of cooling towers, which are essential for regulating temperatures in a wide range of industrial processes. Cooling towers use fill packs to enhance the heat exchange process by creating a large surface area for water to spread across, promoting efficient evaporation. Over time, fill packs can degrade due to factors such as water quality, exposure to UV rays, temperature fluctuations, or mechanical damage. When the fill material becomes fouled, cracked, or worn out, it compromises the cooling tower’s ability to effectively cool water, leading to inefficiencies in the system. This inefficiency results in higher energy usage, greater wear on other components, and increased operational costs. Timely replacement of the fill pack ensures that the cooling tower operates at peak efficiency, minimizing downtime and preventing more costly damage to other components in the system.

Key Points:

Understanding the Function of Fill Packs:

-

- Fill packs are designed to provide a large surface area for water as it flows through the cooling tower. The water flows in a thin film over the fill, which increases the contact between the water and the air, facilitating the evaporation process. This heat exchange process is what cools the water down and allows the cooling tower to release heat efficiently into the atmosphere.

Why Fill Packs Get Damaged:

-

- Scaling: In areas with hard water, mineral deposits can accumulate on the fill surface, reducing the surface area available for heat exchange and leading to inefficiency in cooling.

- Fouling: The build-up of dirt, organic materials, or biological growth like algae can clog the fill and impede water flow. This reduces the heat exchange efficiency and can eventually damage the fill.

- UV Degradation: Fill packs are often exposed to UV rays, which can cause the material to degrade over time, leading to brittleness and cracks.

- Physical Damage: Exposure to high temperatures, physical wear, or freezing conditions can cause cracks or distortion in the fill packs, which impacts their effectiveness.

Signs That Indicate Fill Pack Replacement Is Needed:

-

- Reduced Cooling Efficiency: If the cooling tower is unable to cool water to the desired temperature, the fill may have lost its effectiveness. This can result in a higher temperature of the water being discharged.

- Energy Consumption Increase: As fill packs degrade, the cooling system has to work harder to achieve the desired cooling, leading to increased energy consumption and higher operational costs.

- Visible Cracks and Damage: Physical damage such as cracks, warping, or brittleness in the fill material indicates the need for replacement. Over time, mechanical stresses or weather conditions can cause the fill to break down.

- Unusual Noise or Vibration: A malfunctioning fill pack may cause unusual vibrations or noises in the cooling tower as the water flow is disrupted.

The Fill Pack Replacement Process:

-

- Inspection: A detailed inspection of the fill material is the first step in the replacement process. This involves checking for visible cracks, scaling, fouling, and any signs of degradation. The entire cooling tower system, including fans, pumps, and other components, should also be checked for issues that may affect fill performance.

- Cleaning: Before replacing the fill packs, the cooling tower is thoroughly cleaned. This includes flushing out debris, removing any scale or organic growth, and cleaning the water distribution system.

- Removal of Old Fill: The old fill material is carefully removed, ensuring that no debris or particles remain that could clog the new fill. This step may also involve cleaning the tower structure if necessary.

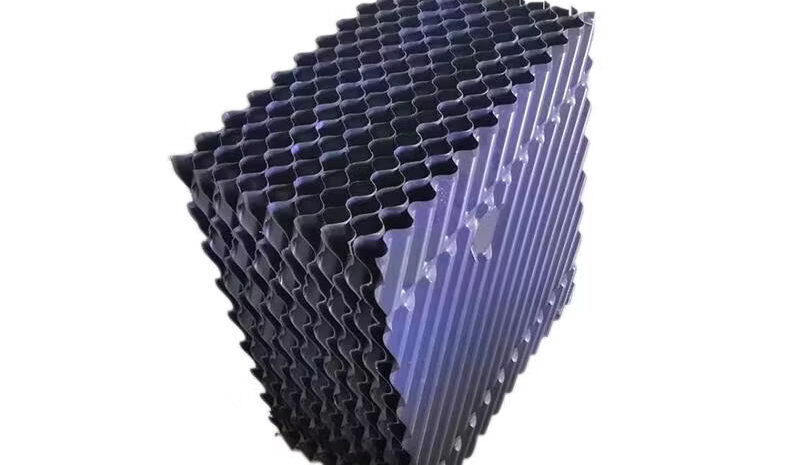

- Installation of New Fill Packs: New fill material, typically made from high-quality PVC or other durable plastic materials, is installed to match the original specifications of the cooling tower. It is essential to ensure that the new fill material fits properly to maintain uniform water distribution and heat exchange efficiency.

- Testing and Adjustment: After the replacement, the cooling tower system is tested to ensure that the new fill is performing as expected. Adjustments to the water flow, air handling, and fan speed may be necessary to optimize the system’s performance.

Types of Fill Packs:

-

- Splash Fill: This type of fill is often used in smaller or less demanding cooling systems. The water is splashed over the fill, and the heat exchange happens as air moves through the system.

- Film Fill: Film fill is used in larger, industrial systems where higher performance is required. It creates a thin film of water that increases the surface area for heat exchange, allowing for better cooling efficiency.

- Hybrid Fill: Some cooling towers use a combination of splash and film fills, providing a balance of high heat transfer and resistance to fouling.

Materials Used for Fill Packs:

-

- PVC (Polyvinyl Chloride): This is the most commonly used material for fill packs due to its durability, resistance to corrosion, and ease of cleaning.

- PP (Polypropylene): This material is used in environments with higher temperatures or where PVC might degrade, as it has better heat resistance.

- Wood and Metal: In older cooling towers, wood or metal may still be used for fill packs, although these materials are less common today due to their susceptibility to corrosion and biological growth.

Benefits of Regular Fill Pack Replacement:

-

- Improved Cooling Efficiency: New fill packs restore the cooling tower’s ability to efficiently transfer heat from the water to the air, resulting in improved system performance and reduced energy consumption.

- Extended Equipment Life: Regular maintenance and replacement of fill packs help prevent more significant issues that could lead to costly repairs or replacements of other components, thus extending the overall life of the cooling tower.

- Lower Maintenance Costs: By replacing the fill packs before they cause major issues, companies can avoid the need for expensive repairs or downtime due to system failure.

Economic and Environmental Benefits:

-

- Energy Savings: An efficient cooling tower consumes less power to operate, leading to reduced operational costs and a smaller carbon footprint.

- Water Conservation: By maintaining optimal cooling tower performance, less water is wasted due to inefficiency, contributing to better water conservation.

Long-Term Considerations:

-

- Material Selection: Choosing high-quality, durable materials for the fill packs can reduce the frequency of replacements and ensure the longevity of the cooling tower.

- Prevention of Fouling and Scaling: Regular maintenance, including water treatment and cleaning, can prevent the build-up of scale and fouling, which can extend the life of the fill packs and improve overall system performance.

- Technological Advancements: New materials and technologies for cooling tower fills are emerging that offer improved performance and energy savings, such as advanced anti-fouling coatings or designs that reduce water and energy consumption.

Conclusion

fill pack replacement is a crucial maintenance procedure that directly impacts the performance, energy efficiency, and longevity of a cooling tower. Properly maintained fill packs ensure that the cooling tower continues to effectively dissipate heat, keeping energy consumption low and operational costs manageable. When fill packs are allowed to degrade, they reduce the overall efficiency of the system, which can lead to higher energy bills, increased wear on other components, and potentially more frequent system breakdowns. By replacing worn-out fill packs, companies can not only improve the cooling performance but also extend the lifespan of the cooling tower.