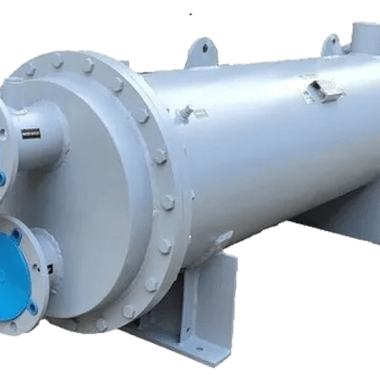

Finned Tube Heat Exchanger

FINNED TUBE HEAT EXCHANGER

The major parts of heat exchangers are finned tubes. They are a collection of tubes with fins added to the exterior. Also, to improve the fluid’s contact area, and exchange heat. As well as allow the fluid inside the tube and fluid outside the tube to communicate more effectively. The fin strip is welded to the tube along the spiral root after being twisted spirally onto the tube.

In other words, The exchanger’s exterior tube is enhanced with fins. Fins make it easier to move liquids outside of the tube. It is used to move air or another gas. An overall flow pattern in a finned tube heat exchanger is frequently cross flow, although it can also be counter flow or parallel flow.

HOW DOES FINNED TUBE HEAT EXCHANGER WORKS?

Fins are located outside of the tubes in a heat exchanger with fins. Air or another gas will be flowing outside while the liquid flows through the finned tube. And because there is more heat transfer surface area, the heat transfer rate is increasing.

Typically, radial circular or square fins are used on crossflow tube exchangers. If there is a counter-flow, the fins should be longitudinal rather than radial, or they can be parallel flow fin tube exchangers. Finned tubes serve as internal tubes in a closed heat exchanger.

ADVANTAGES

- A solid bond between the fin and base tube prevents fins from becoming loose due to heat stress, oxidation, corrosion, etc.

- Use at potentially very high temperatures

- Extruded or drawn fin tubes with two opposing longitudinal fins.

- Used in the construction of boiler walls.

- The benefit over traditional boiler wall construction is that only one weld is needed to join two tubes, eliminating the need for a steel strip.