Grommet Seals

Introduction

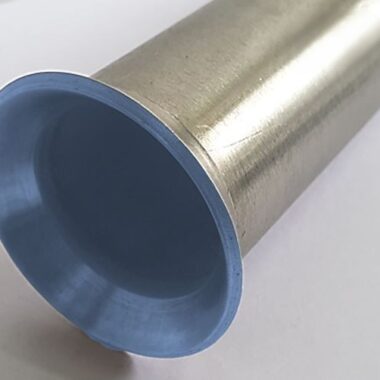

Grommet seals are essential components widely used to protect, insulate, and seal holes or openings in various surfaces. Made from flexible materials such as rubber, silicone, or neoprene, grommets are primarily used in industries like automotive, aerospace, electronics, and manufacturing. These seals play a vital role in safeguarding cables, wires, and hoses from environmental elements such as moisture, dust, chemicals, and physical wear. Their primary functions include preventing damage, reducing vibrations, and providing a reliable, durable seal that enhances the performance and lifespan of components in various applications.

Features and Functions of Grommet Seals

Protection Against Environmental Factors:

-

- Grommet seals effectively protect cables, wires, and components from exposure to moisture, dust, dirt, and chemicals that could cause damage or malfunction.

- In automotive applications, grommet seals prevent water and debris from entering the vehicle, protecting the electrical wiring from corrosion.

Vibration Dampening:

-

- Grommets provide cushioning for cables and other sensitive components, reducing the impact of vibrations that could lead to wear and tear.

- This is particularly important in automotive, aerospace, and industrial machinery where vibrations are frequent and can cause component failure over time.

Prevention of Abrasion:

-

- The rubber or elastomeric material of grommet seals prevents abrasion between the wire or cable and the edges of the hole through which it passes.

- In harsh environments, grommets act as a protective barrier, ensuring that cables or tubes do not get worn out by sharp edges or constant movement.

Easy Installation:

-

- Grommet seals are typically designed for easy installation, requiring no specialized tools. They can be pressed into place and fit snugly into the hole, creating a reliable seal.

- Many grommets feature flanges or ribs that provide a secure fit and help hold the grommet in position, even in high-vibration settings.

Versatility in Material Choices:

-

- Grommet seals are available in various materials, including rubber, silicone, PVC, neoprene, and elastomers. The choice of material depends on the application requirements, such as temperature tolerance, chemical resistance, and flexibility.

- For example, silicone grommets are ideal for high-temperature environments, while neoprene grommets are better for outdoor applications where UV resistance is necessary.

Noise Reduction:

-

- Grommet seals are effective in minimizing noise and vibrations by providing a cushioning effect between components that move or vibrate. This is particularly useful in automotive and industrial machinery.

Applications of Grommet Seals

Automotive Industry:

-

- Grommet seals are widely used in vehicles to protect electrical wiring and cables from the elements, including water, dust, and dirt.

- They are also used to prevent the intrusion of noise, dust, and vibrations into the vehicle’s interior and to seal access points for air conditioning and ventilation systems.

Electronics and Electrical Equipment:

-

- In electronic devices and control panels, grommets provide a protective seal for wires and cables, ensuring that they remain insulated and protected from external conditions.

- Grommet seals are also used in the assembly of electrical components to prevent short circuits and wear on the insulation.

Aerospace Industry:

-

- In aerospace applications, grommet seals are used to protect wiring and sensitive components from environmental hazards such as moisture, temperature extremes, and vibrations.

- They are often used in the assembly of aircraft, satellites, and other aviation equipment where reliability and safety are critical.

Industrial and Machinery Applications:

-

- Grommet seal play a crucial role in industrial machinery, where they protect cables, tubes, and hoses from abrasion, moisture, and chemicals.

- They are often used in factories, manufacturing plants, and heavy machinery to prevent wear and tear on critical components.

Marine Industry:

-

- In the marine industry, grommet seal are used to protect wiring systems from exposure to seawater, moisture, and corrosion.

- They are essential in sealing holes in hulls, engine rooms, and electrical control systems on boats and ships.

Building and Construction:

-

- Grommet seals are used in building applications for waterproofing and insulating pipes and cables that pass through walls, floors, and ceilings.

- They help to prevent water and air leaks, which is especially important for energy efficiency and safety in commercial and residential buildings.

Benefits of Grommet Seal

Cost-Effective:

-

- Grommet seal are relatively inexpensive compared to other sealing solutions. They provide an efficient way to protect and insulate cables, wires, and hoses without the need for complex sealing systems.

Durability:

-

- Made from strong and flexible materials, grommet seals are durable and long-lasting. They can withstand harsh environments, UV exposure, and temperature fluctuations, ensuring reliable performance over time.

Improved Safety:

-

- By preventing cables from being exposed to hazardous conditions and reducing the risk of electrical shorts or abrasion, grommet seals enhance the safety of electrical and mechanical systems.

Enhanced Aesthetics:

-

- Grommet seal often help in creating a neat, finished appearance by concealing holes and providing a clean, smooth edge around wires and cables.

Conclusion

Grommet seal are simple yet highly effective solutions that ensure the protection and longevity of cables, wires, and sensitive components in harsh environments. Their versatility, ease of installation, and durability make them indispensable in a variety of industries, from automotive to aerospace. By preventing moisture, dust, and physical wear, grommet seals contribute to improved safety, performance, and cost-efficiency of systems. As industries continue to evolve, the demand for reliable sealing solutions like grommets will remain crucial for maintaining the integrity and functionality of critical applications.