How do Cooling Towers Operate in Cold and Sub-zero Weather ?

How do Cooling Towers Operate in Cold and Sub-zero Weather ?

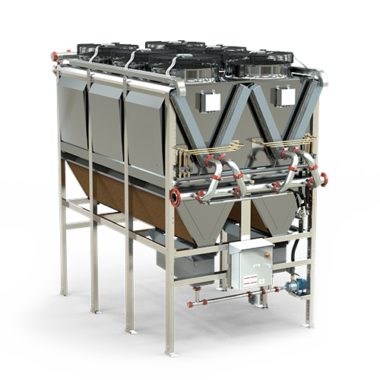

Cooling towers are designed to function efficiently in a wide extend of surrounding temperatures, counting cold and sub-zero climate conditions. How do Cooling Towers Operate in Cold and Sub-zero Weather?, Whereas cooling towers ordinarily dissipate heat by evaporating water, they can still work effectively in cold climate with a few adaptations:

Winterization:

- Cooling towers can be winterized to protect against solidifying temperatures. This may include draining the tower bowl and channeling system to avoid water from freezing and causing damage to components. A few cooling towers are prepared with winterization highlights such as heaters or heat following to avoid solidifying in critical areas.

Low Ambient Temperature Operation:

- Numerous cooling towers are outlined to function in low ambient temperatures without freezing. A few models have controls that consequently alter fan speed or water flow to optimize execution in cold climate conditions whereas preventing freezing. Additionally, cooling towers with variable speed fans can decrease airflow to preserve optimal water temperature without overcooling.

Anti-freeze Additives:

- In regions with prolonged periods of sub-zero temperatures, anti-freeze additives can be used to lower the freezing point of the water within the tower bowl. Propylene glycol may be a common additive used to anticipate solidifying in cooling tower systems. By including the suitable concentration of anti-freeze to the water, cooling towers can continue to function safely in cold climate conditions.

Winter Maintenance:

- Regular maintenance is fundamental for guaranteeing the proceeded operation of cooling towers in cold climate. This incorporates inspecting and testing radiators, pumps, valves, and other components to guarantee they are working accurately. Moreover, removing snow and ice buildup from the tower structure and get to focuses helps maintain wind current and prevents damage to the tower.

Insulation:

- Insulating basic components of the cooling tower, such as channeling, valves, and controls, can help anticipate heat loss and freezing in cold weather. Cover materials such as froth or fiberglass can be connected to exposed surfaces to hold heat and ensure against freezing.

Monitoring and Control:

- Continuous monitoring of temperature, water stream, and system weight is fundamental amid cold climate operation. Automated controls and alerts can alert administrators to potential freezing conditions or other issues, permitting for prompt action to anticipate damage and guarantee the safety and unwavering quality of the cooling tower system.

By executing these measures, cooling towers can proceed to operate effectively and productively even in cold and sub-zero weather conditions, guaranteeing uninterrupted cooling execution for industrial processes, HVAC frameworks, and other applications.