How Dry Cooling Tower Works ?

How Dry Cooling Tower Works ?

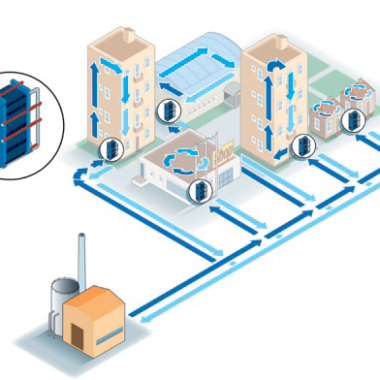

How Dry Cooling Tower Works ? : Dry cooling towers are a sort of heat rejection gadget commonly utilized in industrial and power plant applications to dissipate waste heat into the climate. Not at all like conventional wet cooling towers, dry cooling towers don’t utilize water to cool the method fluid. Instep, they depend on air to exchange heat. Here’s a detailed clarification of how dry cooling towers work:

Components of a Dry Cooling Tower

Heat Exchanger (Air-cooled):

Finned Tubes: Tubes with amplified surfaces (balances) to extend the heat transfer area.

Tube Bundles: Courses of action of finned tubes through which the hot handle fluid streams.

Fans:

Axial Fans: Expansive fans that draw or force air through the heat exchanger.

Constrained Draft or Induced Draft Fans: Depending on the plan, fans can be put to either push air into (forced draft) or pull air through (induced draft) the heat exchanger.

Casing and Structure:

Enclosure: A housing that bolsters the heat exchanger and fans, giving structure and coordinating airflow.

Working Principle

Hot Fluid Circulation:

- The process liquid (regularly water, oil, or another coolant) that must be cooled is pumped into the dry cooling tower.

- The hot liquid streams through the finned tubes of the heat exchanger.

Air Flow:

- Large fans make a ceaseless flow of surrounding air through the heat exchanger.

- In a constrained draft system, fans are found at the base, pushing air through the heat exchanger.

- In an actuated draft system, fans are found at the beat, pulling air through the heat exchanger.

Heat Transfer:

- As the hot process fluid streams through the finned tubes, the heat is exchanged from the fluid to the tube dividers and then to the blades.

- The fins significantly increase the surface range for heat exchange, upgrading the cooling prepare.

- The encompassing air absorbs the heat from the fins because it flows over them.

Cooled Fluid Return:

The now-cooled prepare fluid exits the heat exchanger and is recycled back into the system or handle from which it came.

Exhaust Air:

The heated air, having ingested heat from the balances, is expelled into the air, completing the cooling cycle.

Advantages of Dry Cooling Towers

Water Preservation:

Since dry cooling towers don’t utilize water for heat rejection, they are perfect for areas with limited water assets or strict water utilization controls.

Reduced Environmental Affect:

No water vapor plume is created, minimizing visual affect and potential natural concerns related with water cooling strategies.

Lower Maintenance:

Dry cooling towers generally require less support than wet cooling towers since they don’t suffer from issues related to water quality, scaling, and biological growth.

Consistent Execution:

Execution is less influenced by variations in water quality and accessibility, providing more predictable cooling capabilities.

Disadvantages of Dry Cooling Towers

Higher Initial Costs:

Dry cooling towers typically have higher beginning capital costs due to the complexity and estimate of the heat exchanger and fan systems.

Larger Footprint:

They for the most part require more space than wet cooling towers, as the heat exchange surface zone needs to be huge to compensate for the lower heat transfer productivity of air compared to water.

Efficiency Limitations:

The cooling efficiency is constrained by the encompassing air temperature; as the air temperature rises, the cooling capacity decreases.

Applications

Power Plants: Utilized to cool steam condensers in thermoelectric power plants, particularly in arid regions.

Industrial Processes: Reasonable for businesses where water usage is limited or where high-quality cooling water is required.

HVAC Systems: Utilized in commercial and residential HVAC systems where water preservation may be a priority.

Conclusion

Dry cooling towers give an efficient and environmentally inviting solution for heat dissipation without the utilize of water. By leveraging the standards of air-based heat transfer, these systems offer significant preferences in terms of water preservation and support, making them an perfect choice for various industrial and power generation applications. However, their higher starting costs and bigger footprint have to be be considered within the planning and implementation stages.

The Benefits of using Cooling Tower - Cool Fab Equipments August 06, 2024 at 2:32 pm

[…] Cooling towers are basic components in different industrial and commercial applications, giving an productive means of heat dissipation. By utilizing the standards of evaporation and heat exchange, cooling towers help maintain ideal temperatures in systems, guaranteeing proficient operation and longevity. Here are the benefits of using cooling tower : […]