Learn about Multicell Cooling Towers

Learn about Multicell Cooling Towers

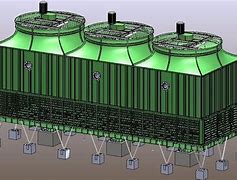

Multicell cooling towers are commonly utilized in oil refining, petrochemical, and power-generation facilities to effectively dissipate heat created by different industrial processes. These towers comprise of different cells, each prepared with heat exchange components such as fill media, fan assemblies, and drift eliminators. Here’s learn about how multicell cooling towers are utilized in these businesses:

1) Oil Refining:

- Oil refining processes produce expansive amounts of heat that must be expelled to preserve optimal operating conditions and item quality. Multicell cooling towers are utilized to cool circulating water used in refinery processes such as crude oil refining, liquid catalytic cracking, and hydrotreating.

- In oil refineries, multicell cooling towers regularly operate in conjunction with heat exchangers to transfer heat from handle streams to the cooling water. The cooled water is at that point recirculated through the cooling tower, where heat is dissipated to the air through evaporation and convection.

2) Petrochemical Industry:

- Petrochemical plants utilize multicell cooling towers to cool handle liquids in different manufacturing forms, including polymerization, chemical amalgamation, and gas preparing. These forms produce heat that must be evacuated to maintain response rates and product quality.

- Multicell cooling towers play a vital part in petrochemical plants by giving efficient heat rejection for hardware such as heat exchangers, reactors, and refining columns. The cooled water circulated through the cooling tower helps maintain optimal operating temperatures for these processes.

3) Power Generation:

- Power-generation offices, counting coal-fired, normal gas-fired, and atomic control plants, depend on multicell cooling towers to disseminate heat from control era hardware, such as steam turbines and condensers. These offices require large quantities of cooling water to condense steam and maintain thermal effectiveness.

- Multicell cooling towers are commonly utilized in control plants as portion of a closed-loop cooling system, where water is circulated between the power generation hardware and the cooling tower. The cooling tower expels heat from the circulating water, allowing it to be reused within the control generation prepare.

Key benefits of using multicell cooling towers in these industries include:

- Scalability: Multicell plan allows for easy expansion and modification to accommodate changing cooling requirements.

- Redundancy: Multiple cells give excess and operational adaptability, ensuring uninterrupted cooling indeed during maintenance or equipment downtime.

- Efficiency: Proficient heat exchange and thermal performance help optimize energy consumption and operating costs.

- Durability: Robust construction and corrosion-resistant materials ensure long-term reliability and performance in harsh industrial situations.

Overall, multicell cooling towers are basic components in oil refining, petrochemical, and power-generation facilities, playing a basic role in maintaining handle efficiency, equipment reliability, and environmental compliance.

Understand the flexibility and expandability of Multicell Cooling Towers - Cool Fab Equipments March 22, 2024 at 4:47 pm

[…] Multicell cooling towers offer significant flexibility and expandability, making them appropriate for a wide range of cooling applications in different industries. How to Understand the flexibility and expandability of Multicell Cooling Towers : Here’s how multicell cooling towers give flexibility and expandability: […]