Leveraging Artificial Intelligence

Introduction

Leveraging Artificial Intelligence for predictive maintenance in cooling systems is revolutionizing the way industries maintain and optimize their equipment. By utilizing machine learning algorithms and real-time data analysis, AI enables cooling systems to operate with greater efficiency, accuracy, and reliability. Predictive maintenance powered by AI anticipates system failures before they occur, reducing downtime, minimizing repair costs, and extending the lifespan of critical components. This innovative approach not only enhances operational performance but also aligns with sustainability goals, making it a key driver in the future of energy-efficient cooling solutions.

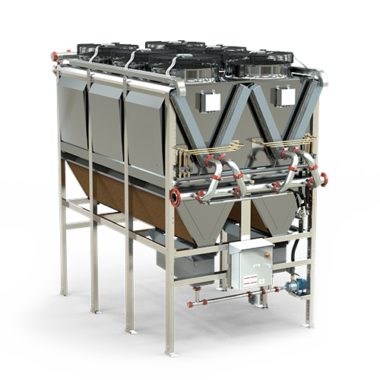

- Real-Time Monitoring: AI-driven systems can continuously monitor various parameters such as temperature, pressure, airflow, and vibration in cooling systems. This real-time data provides critical insights into the health of components like fans, compressors, and pumps, enabling early detection of anomalies.

- Data-Driven Predictions: AI algorithms use historical data and advanced analytics to predict when and where failures are likely to occur. By analyzing patterns, AI can identify potential issues like component wear or system inefficiencies before they escalate into costly problems.

- Reducing Downtime: By forecasting maintenance needs, AI allows for planned maintenance during non-peak hours, minimizing system downtime and preventing sudden breakdowns that can disrupt operations.

- Optimized Energy Efficiency: Predictive maintenance ensures that cooling systems are always operating at peak performance, reducing energy consumption. AI helps identify inefficiencies in real-time and provides suggestions for optimization, such as adjusting airflow or reducing compressor load during off-peak times.

- Cost Savings: AI-based predictive maintenance significantly reduces maintenance costs by avoiding unnecessary service checks and preventing major failures that require expensive repairs or replacements.

- Improved Lifespan of Equipment: With predictive maintenance, cooling system components experience less wear and tear, as issues are addressed early. This leads to an extended lifespan of equipment and less frequent need for replacements.

- Enhanced Fault Diagnosis: AI algorithms can identify the root causes of system inefficiencies or malfunctions more accurately than traditional methods. For example, AI can differentiate between issues caused by airflow blockages, refrigerant leaks, or worn-out mechanical components, helping maintenance teams address the exact problem faster.

- Automated Alerts and Action: AI-driven systems can send automated alerts when a potential issue is detected, ensuring immediate action can be taken. Some advanced AI systems can even initiate corrective measures automatically, such as adjusting system settings or switching to backup components to avoid interruptions in cooling.

- Customized Maintenance Plans: Instead of following a one-size-fits-all maintenance schedule, AI allows for the development of highly customized maintenance plans based on the unique operating conditions and requirements of each cooling system. This tailored approach improves system efficiency and reduces unnecessary interventions.

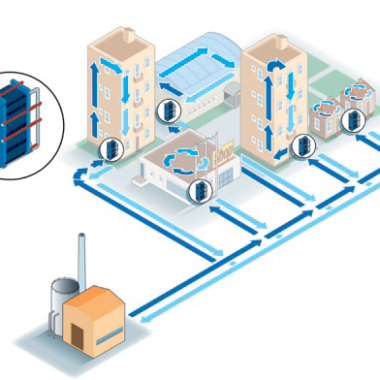

- Integration with IoT Devices: AI can work in tandem with Internet of Things (IoT) devices, collecting and analyzing data from multiple sources like sensors embedded throughout the cooling system. This connectivity enables a more comprehensive view of the system’s health and performance, improving predictive maintenance outcomes.

- Proactive Response to Environmental Changes: AI can factor in external conditions such as changes in temperature, humidity, or building occupancy, and adjust the cooling system accordingly. This proactive approach helps maintain optimal performance and reduces energy usage by avoiding overcooling or undercooling in response to dynamic environmental conditions.

- Data Visualization for Better Insights: AI-powered systems often provide intuitive dashboards and visual reports that allow facility managers to easily interpret data and trends over time. This visibility into system performance aids in strategic decision-making regarding upgrades, system replacements, or operational adjustments.

- Minimizing Human Error: By automating the monitoring and diagnostics process, AI reduces the risk of human error in maintenance and troubleshooting. Leveraging Artificial Intelligence Predictive maintenance algorithms are designed to detect even the smallest anomalies, which might be overlooked by manual inspections.

Conclusion

leveraging artificial intelligence for predictive maintenance in cooling systems is transforming traditional maintenance practices into proactive, data-driven strategies. By predicting potential failures and optimizing performance in real-time, AI enhances system reliability, reduces downtime, and extends equipment lifespan. The integration of AI not only lowers operational costs but also contributes to sustainability efforts by minimizing energy consumption and resource waste. As cooling technologies evolve, AI-driven predictive maintenance is set to become an essential tool for achieving higher efficiency and long-term cost savings across industries.