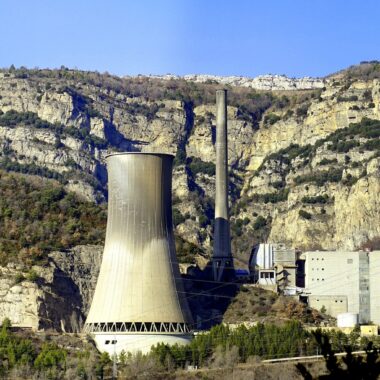

Manufacturer Natural draft cooling Tower

Manufacturer Natural draft cooling Tower

Manufacturer Natural draft cooling Tower

The natural draft cooling tower is an open, direct-contact system. It works using a heat exchanger, allowing hot water from the system to be cooled through direct contact with fresh air. To increase the heat transfer surface area (and optimize the cooling process), hot water is sprayed from nozzles within the tower.

Natural draft cooling towers are frequently used in power plants. The tower’s stack effect is responsible for producing the necessary air stream volume for cooling. These models offer a unique economic advantage in that the energy requirement is extremely low. This means, of course, that operating costs are minimal.

- Main Equipment. A natural-draft cooling tower (NDCT), on the other hand, is preferred for

- Solar Thermal Systems: Components and Applications.

- Waste heat rejection methods in geothermal power generation. An indirect cooling method

- Cooling towers. Perhaps the most common environmental requirement in modern cooling

Principle of natural draft cooling tower. The warm water you wish to cool inside the cooling tower is pumped from the top of the building at an inlet of warm water.Building such a tower is expensive and time-consuming. To overcome the typical expenses associated with RC natural draft cooling towers, and improve economics for small-scale towers

The Natural draft cooling towersare particularly pretty as a cost-saving solution for power plants and other industrial plants requiring larger quantities of cooling water. Natural Draft cooling tower operates without fans and Fills, the large.Natural draft cooling towers (natural convection cooling towers) use the principle of convective flow to provide air circulation. They are tall in order to induce adequate air flow.

Natural draft cooling towers are frequently used in power plants. The tower’s stack effect is responsible for producing the necessary air stream volume for cooling. These models offer a unique economic advantage in that the energy requirement is extremely low. This means, of course, that operating costs are minimal.

Refrigerated air dryers work by cooling the air around them and making it cooler, thus condensing a lot of the water vapor. Refrigerated dryers can make the air reach dew points around 36 degrees F, but it cannot achieve a dew point below freezing. That means that there’s still some water vapor leftover in the air.A refrigerated air dryer is the most commonly used. type of compressed air dryer / Gas Dryer for most plant applications for the drying of plant air and other utility gases like Seal gas , hydrogen gas for generator cooling , nitrogen Gas drying etc. where a dew point of (+2) Deg. C. at line pressure i.e. (-22 )Deg. C. at atmospheric pressure) is an acceptable norm.