Microchannel Heat Systems

Introduction

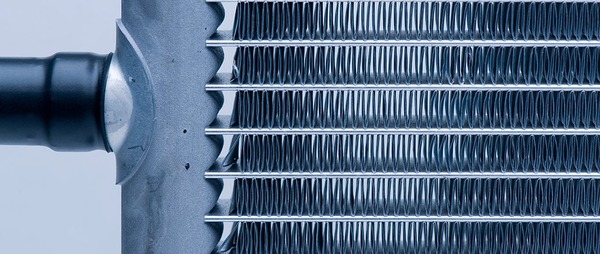

Microchannel heat systems are a revolutionary advancement in the field of thermal management, designed to enhance the efficiency of heat transfer processes while minimizing the size and complexity of traditional heat exchangers. These systems use a series of small, parallel channels to allow the movement of fluids, facilitating rapid and effective heat exchange in compact and lightweight units. Microchannel heat exchangers are highly valued in industries that require high performance in constrained spaces, such as automotive, electronics, and renewable energy. They are also seen as environmentally friendly due to their reduced refrigerant volume and lower energy consumption. As global demand for more efficient and sustainable technologies continues to rise, microchannel heat systems have become an essential solution for applications where space, energy efficiency, and thermal performance are crucial factors. These heat systems offer unique advantages, including improved heat transfer efficiency, reduced maintenance costs, and greater durability in demanding environments. The design of microchannel exchangers, with their narrow channels and higher surface area, allows them to outperform traditional heat exchangers, enabling them to handle high heat loads with less fluid and energy.

Key Features of Microchannel Heat Systems:

-

Compact Design:

Microchannel heat exchangers are designed with small channels that are highly packed together. The density of these channels allows them to transfer heat effectively in a much smaller volume compared to traditional heat exchangers. This compact design helps save valuable space in applications like automotive air conditioning systems, small appliances, or portable electronics. The reduced footprint ensures these heat exchangers can be fitted into tight spaces while delivering efficient cooling. -

Improved Heat Transfer Efficiency:

The unique feature of microchannels is their increased surface area-to-volume ratio. By having many small channels packed closely together, the heat exchange surface is maximized. This significantly boosts heat transfer efficiency, enabling the system to remove heat faster. In practice, this means microchannel heat exchangers can cool systems more effectively with less coolant, making them more efficient than traditional fin-and-tube heat exchangers. This improved efficiency is especially useful in environments with high heat loads, like electric vehicle batteries and high-performance electronics. -

Lightweight and Cost-effective:

Microchannel heat exchangers are often made from lightweight materials like aluminum, which not only reduce the overall weight of the system but also lower the cost of manufacturing. This is a crucial benefit for industries like automotive manufacturing, where every pound saved on weight directly improves fuel efficiency or vehicle performance. The lightweight nature also makes these systems easier to transport and handle during installation or maintenance, ultimately reducing logistical and operational costs. -

Reduced Fluid Volume:

Traditional heat exchangers often require large amounts of coolant or refrigerant to operate efficiently. In contrast, microchannel heat exchangers use smaller quantities of fluid because of their small, efficient channels. This reduced fluid volume results in lower energy consumption and reduced environmental impact. In systems like air conditioning or refrigeration, reducing the amount of refrigerant also minimizes the need for expensive, harmful chemical refrigerants, aligning with sustainability goals and regulations. -

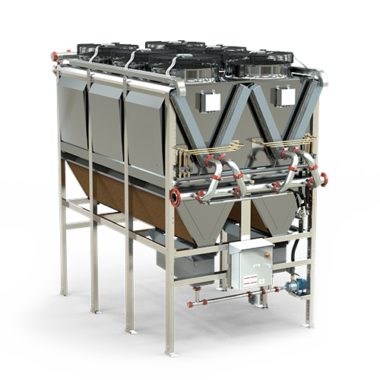

Enhanced Performance in High-Flow Conditions:

Microchannel heat exchangers perform exceptionally well in high-flow conditions due to their design. The channels are optimized for fluid movement, allowing them to handle high flow rates effectively without compromising on heat transfer. This makes them ideal for applications with high thermal loads or varying fluid flow, such as in car engines, turbochargers, and HVAC systems in large commercial buildings. The higher density of the channels also allows the system to accommodate higher pressure drops, further enhancing its capability in challenging environments. -

Low Maintenance:

Microchannel heat exchangers are inherently easier to clean and maintain than their larger counterparts due to their smaller size and fewer components. Their compact design reduces the buildup of debris, dirt, and scale, which can often obstruct heat flow. Additionally, the design allows for easy access to the internal components, making it simpler for technicians to inspect and clean the heat exchanger when necessary. This lowers maintenance costs and extends the system’s lifespan, especially in industrial or commercial applications where continuous operation is critical. -

Durable and Corrosion-Resistant:

Microchannel heat exchangers are constructed from corrosion-resistant materials like aluminum or copper, often treated with coatings that further protect them from environmental wear and tear. These materials can withstand extreme conditions, including exposure to chemicals, moisture, or high-temperature fluctuations, making them durable over time. The ability to resist corrosion is particularly important in automotive, aerospace, and marine applications where heat exchangers are exposed to harsh environmental conditions.

Applications of Microchannel Heat Systems:

-

Automotive HVAC Systems:

In the automotive industry, the cooling of air conditioning systems is critical to maintaining passenger comfort. Microchannel heat exchangers are widely used in automotive HVAC systems because they provide superior cooling efficiency while saving space and reducing weight. Their high thermal performance allows vehicles to cool faster and use less refrigerant, contributing to better fuel efficiency and lower environmental impact. Microchannel exchangers also enable smaller, more compact air conditioning units, which is a big advantage in modern vehicle design. -

Refrigeration:

Microchannel heat exchangers are increasingly being used in refrigeration systems, both in residential and commercial applications. Their improved heat transfer efficiency reduces the overall energy consumption of the system. They can be found in home refrigerators, walk-in coolers, and large industrial freezers. Microchannel systems are especially beneficial in systems that require compact and lightweight solutions, like portable coolers or small-scale refrigeration units, where space is often limited. -

Electronics Cooling:

The electronics industry has seen a massive increase in the need for efficient cooling solutions due to the growing power density of components like CPUs, GPUs, and power electronics. Microchannel heat exchangers are ideal for cooling high-performance electronics because they provide effective thermal management in a small, lightweight package. These systems help dissipate heat from critical electronic components, ensuring optimal performance and preventing overheating, which could lead to device failure. -

Renewable Energy:

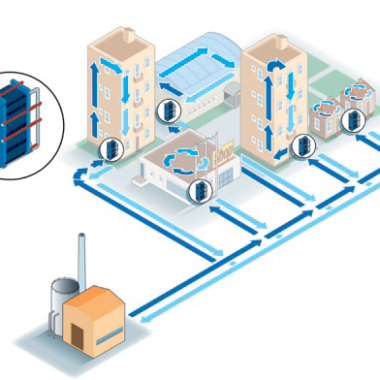

Microchannel heat exchangers play an important role in renewable energy applications such as solar thermal systems and geothermal heat pumps. In solar thermal systems, they help to collect and transfer heat efficiently from solar collectors to the storage systems. Similarly, in geothermal heat pumps, microchannel exchangers are used to transfer heat between the building and the earth, improving the overall energy efficiency of the system. Their small size, coupled with high thermal efficiency, makes them ideal for renewable energy systems that prioritize low energy consumption and reduced space usage. -

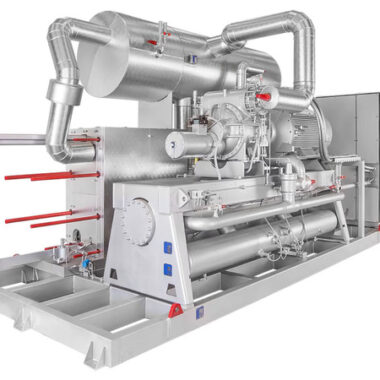

Industrial Applications:

Microchannel heat exchangers are widely used in industrial cooling applications, including cooling machinery, process cooling, and chemical reactors. In industrial settings, where maintaining optimal temperatures is crucial for production efficiency, microchannel heat exchangers provide a highly efficient, reliable cooling solution. These systems can handle high thermal loads and provide robust cooling performance, even in challenging conditions where other types of heat exchangers might struggle. -

Air Conditioning and Heat Pump Systems:

The use of microchannel heat exchangers in commercial HVAC systems and heat pumps has grown significantly due to their efficiency, compact design, and lower refrigerant requirements. These systems are used to regulate the temperature in buildings, providing both heating and cooling. Microchannel exchangers in heat pump systems allow for better energy efficiency and performance, particularly in applications that require rapid temperature control in tight spaces, like server rooms, hospitals, or residential buildings.

Advantages:

-

Efficiency in Space-Limited Applications:

The small, compact nature of microchannel heat exchangers allows them to be deployed in environments where space is at a premium. This is particularly important in industries like automotive and electronics, where systems must be designed to fit in limited space without sacrificing performance. Microchannel heat exchangers maximize the available area, providing a high level of thermal management without requiring a large physical footprint. -

Energy Savings:

Because microchannel heat exchangers require less fluid to operate and offer more efficient heat transfer, they result in lower energy consumption compared to traditional heat exchangers. This is particularly beneficial in long-term applications, where reducing operational costs is a priority. The efficient use of energy and refrigerant helps minimize electricity bills and environmental impact, contributing to both cost and resource savings. -

Environmental Benefits:

Microchannel heat exchangers are an environmentally friendly alternative to traditional heat exchangers. Their reduced refrigerant volume minimizes the impact on the environment by lowering greenhouse gas emissions, especially in systems where refrigerant leakage can occur. Additionally, the use of lightweight, corrosion-resistant materials helps these systems last longer, further contributing to sustainability efforts by reducing the need for replacements and repairs. -

Customization:

One of the key benefits of microchannel heat exchangers is their flexibility. These systems can be customized to fit specific needs based on channel sizes, material selection, and performance requirements. Whether the application involves cooling for a small household appliance or a large industrial system, microchannel heat exchangers can be tailored to deliver optimal results, making them highly versatile across various industries.

Conclusion

Microchannel heat systems stand at the forefront of innovation in the realm of thermal management, offering solutions that meet the dual needs of enhanced performance and space efficiency. Their ability to provide superior heat transfer with minimal fluid volume makes them an indispensable part of modern engineering, particularly in industries where energy consumption and compact design are critical considerations. These systems are not only more efficient but also environmentally friendly, reducing both operational costs and the ecological impact by requiring less refrigerant and consuming less energy. As industries strive to meet higher standards of performance, sustainability, and cost-effectiveness, microchannel heat exchangers offer a future-proof solution that addresses these needs head-on. With applications spanning from automotive to electronics, renewable energy, and beyond, the versatility of microchannel heat systems ensures they will continue to play a pivotal role in shaping the future of thermal management. As technology advances and new challenges arise, these systems will remain a key component in the ongoing quest for more efficient, reliable, and sustainable heat transfer solutions.