Need for Cross Flow Cooling Tower

Need for Cross Flow Cooling Tower

Functioning

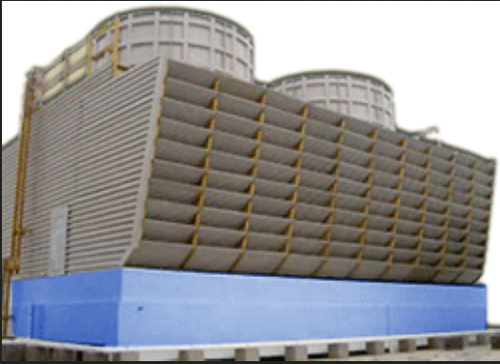

Similar operating principles apply to the crossflow cooling tower as they do to conventional cooling towers. As it flows through the fills, it increases the water’s surface area. It cools the water by convective heat transfer to the air that is going by. Due to crossflow, the phrase “crossflow,” the water flows down the fills vertically but the air contacts it horizontally. To guarantee that the water falling over the fill medium is spread evenly, a hot water basin is frequently used while building a cross-flow cooling tow.

Space Requirements

A cross-flow cooling tower requires a sizable plan area. With only two air inlets, a cross-flow tower is better suited for locations where the installation of large fans may be challenging. A cross-flow cooling tower is shorter in height due to the fill’s vertical placement. As a result, to construct this kind of cooling tower, a cooling tower maker needs a higher surface area but a lower height.

Maintenance

Crossflow cooling towers are simpler to maintain because the plenum may be accessed for equipment repairs inside. Additionally, the distribution basin’s nozzles are always accessible. Crossflow cooling towers are made in such a way that it is feasible to enter the mid-plenum and look at the mechanical components and drift eliminators from below, even when the tower is in use. Additionally, access, inspection, cleaning, and even replacement of the cross-flow arrangement nozzles for the cooling towers are all possible.

Water Distribution

The process water is forced to the top of the tower where it is released into a hot water basin by nozzles. The height of the water above the nozzles is the main factor in the nozzles’ gravitational propulsion. For selecting a condenser water pump for this cooling tower, only the distance from the pump to the tower’s peak. And the friction loss in the pipe—along with any flow control valves—must be taken into account.

Variable Flow

It can use as little as 30% of the design flow while ensuring uniform water distribution over the fill by using nozzle cups. Manufacturers can accurately predict the performance of the tower by seeing a constant pressure drop over the fill.

These are the factors considered to be the “Need for Cross Flow Cooling Tower”