Noise-dampening chillers

Introduction

Noise-dampening chillers are a breakthrough in modern cooling technology, designed specifically to address the growing concern of noise pollution in various environments. Traditional chiller systems, which are commonly used in industrial, commercial, and residential spaces, often produce significant noise due to their mechanical components like compressors, fans, and pumps. While these systems are essential for regulating temperatures in buildings, manufacturing plants, healthcare facilities, and more, the noise generated can be disruptive and even harmful to human health, leading to stress, reduced productivity, and sleep disturbances. In response to these challenges, noise-dampening chillers were developed to deliver the same high-performance cooling capabilities while minimizing sound output.

These chillers utilize advanced technologies and materials such as soundproof insulation, vibration isolation systems, and quieter operational components, enabling them to operate at a fraction of the noise level of traditional chillers. This makes them an ideal choice for spaces where noise reduction is crucial, such as residential areas, hospitals, office buildings, data centers, and manufacturing facilities.

Key Features of Noise-Dampening Chillers

- Soundproof Insulation

Noise-dampening chillers use specialized insulation materials around critical components such as compressors, pumps, and fans. These materials absorb sound waves, reducing vibrations and preventing noise from escaping into the environment. - Vibration Isolation

Advanced vibration isolation technology is used to reduce the transmission of vibrations from the chiller’s mechanical components to the surrounding structure. Isolators and dampers are typically installed under the chiller or within the system to absorb mechanical vibrations and reduce noise. - Quiet Operation Components

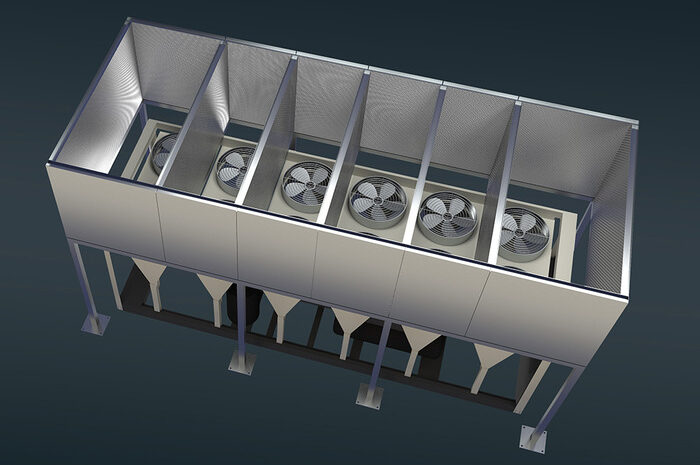

Noise-dampening chillers often feature low-noise fans, high-efficiency compressors, and precision-engineered components that are designed for quieter operation. These components not only reduce mechanical noise but also ensure the system operates at peak performance with minimal sound. - Enclosed Units

Some noise-dampening chillers come in fully enclosed units, which help contain and direct sound away from sensitive areas. These enclosures are designed with soundproofing materials that effectively reduce noise emissions from the chiller system. - Variable Speed Drives (VSDs)

Variable speed drives help adjust the motor speed in response to demand, minimizing unnecessary noise during operation. By controlling the compressor and fan speeds based on the cooling load, these drives help reduce overall sound output when full capacity is not required.

Applications of Noise-Dampening Chillers

- Residential Areas

In residential settings, noise-dampening chillers are perfect for air conditioning systems that need to operate quietly without disturbing the household. Homeowners who live in densely populated areas or close to sensitive spaces, like bedrooms, benefit from the low-noise operation of these chillers. - Office Buildings

Offices that require cooling often need to maintain a professional environment, where noise levels are kept to a minimum. Noise-dampening chillers ensure that HVAC systems do not interfere with communication and productivity. - Healthcare Facilities

In hospitals and medical centers, a quiet environment is essential for patient comfort and recovery. Noise-dampening chillers provide an efficient cooling solution while maintaining a calm and quiet atmosphere in patient rooms, operating theatres, and diagnostic areas. - Data Centers

Data centers house critical equipment that generates a significant amount of heat. Cooling systems in these facilities need to operate continuously without introducing excessive noise, which can disturb sensitive operations or lead to worker fatigue. Noise-dampening chillers address this need by providing quiet, efficient cooling. - Industrial Applications

Industrial environments, where large machinery is often in use, benefit from noise-dampening chillers as they help lower the overall sound levels in manufacturing facilities. This reduction in noise not only improves worker safety and comfort but also complies with noise regulations in certain industries.

Benefits of Noise-Dampening Chillers

- Enhanced Comfort

Quieter operation ensures a more comfortable working and living environment, particularly in sensitive spaces like healthcare facilities, offices, and homes. - Compliance with Noise Regulations

In certain areas, businesses are required to meet noise reduction regulations. Noise-dampening chillers help businesses comply with these regulations without compromising on cooling efficiency. - Increased Productivity

Reducing noise pollution in workspaces or industrial facilities can improve employee focus and productivity. Less ambient noise also leads to better communication and less stress for workers. - Long-Term Durability

By reducing vibration and noise, these chillers often experience less wear and tear, leading to improved durability and longevity. The quieter operation also extends the lifespan of critical components, ensuring a lower total cost of ownership. - Energy Efficiency

Noise-dampening chillers are typically designed with high efficiency in mind. Reduced energy consumption is often a byproduct of improved components like variable speed drives and low-noise fans, which help optimize power usage.

Future Trends in Noise-Dampening Chiller

- Integration with Smart Technology

The future of noise-dampening chillers lies in further integration with IoT and smart technologies. This would allow users to monitor noise levels in real time and adjust the operation of the chiller accordingly, ensuring optimal quietness and energy efficiency. - Advanced Materials for Soundproofing

Future developments will likely bring more advanced materials for soundproofing, enhancing the effectiveness of noise reduction while keeping costs manageable. These materials could be lightweight yet highly effective in absorbing noise. - Further Optimization of Variable Speed Drives

Ongoing improvements in variable speed drive technology will lead to even more efficient and quieter chillers. This technology will allow for better modulation of cooling output and noise levels based on changing load conditions. - Sustainability in Design

As sustainability becomes a priority in all industries, future noise-dampening chiller will likely feature more eco-friendly refrigerants, improved energy efficiency, and longer-lasting components that reduce waste and resource consumption.

Conclusion

noise-dampening chiller represent a significant leap forward in cooling technology, offering both environmental and operational benefits. Their ability to operate quietly while maintaining high performance ensures that they meet the needs of industries and sectors where noise control is as important as temperature regulation. Whether in residential areas, medical facilities, data centers, or industrial environments, these chillers improve the overall quality of life by reducing noise pollution, ensuring comfort, and fostering a more productive and focused atmosphere.

As the world continues to prioritize sustainability and efficiency, the future of noise-dampening chillers looks even more promising. With ongoing advancements in materials, smarter technologies, and energy-saving features, noise-dampening chillers are not only becoming quieter but also more eco-friendly and cost-effective. For businesses and individuals seeking innovative solutions to minimize noise without compromising on cooling performance, these chillers offer the ideal balance of technology, efficiency, and tranquility.