Non-Ferrous Tube Bundles

Introduction

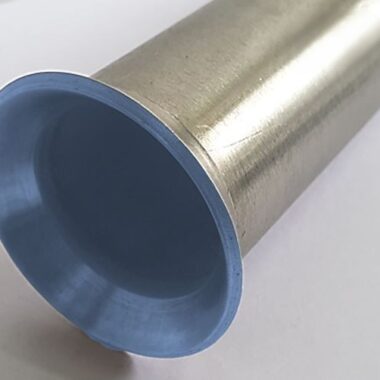

Non-ferrous tube bundles are pivotal components in heat exchangers, providing an optimal solution for systems that require superior heat transfer, corrosion resistance, and durability. Composed of non-ferrous materials like copper, aluminum, brass, and titanium, these tube bundles are specifically designed to operate in harsh environments where ferrous materials would fail due to rust or corrosion. Their excellent resistance to various corrosive elements such as seawater, acids, and chemicals makes them highly suitable for industries such as marine, chemical processing, food and beverage, and HVAC systems. The high thermal conductivity of non-ferrous metals, particularly copper, enhances the efficiency of heat exchangers by improving the overall heat transfer performance. Additionally, non-ferrous tube bundles are durable, lightweight, and versatile, contributing to longer service life and reduced maintenance costs. These qualities position non-ferrous tube bundles as a superior choice for industries focused on performance, reliability, and cost-efficiency.

Innovation in Non-Ferrous Tube Bundle

- Advanced Alloys and Materials: Recent innovations in non-ferrous alloys, such as the development of copper-nickel and titanium-based composites, have significantly improved heat transfer performance and resistance to corrosion. These advanced materials offer enhanced durability and extended service life, even in extreme environments.

- Nanotechnology Integration: Incorporating nanomaterials into the surface of non-ferrous tubes is being explored to further reduce fouling and improve heat exchange efficiency. Nano-coatings can create smoother surfaces that are more resistant to scale buildup, reducing maintenance needs.

- 3D Printing for Custom Tube Bundles: Additive manufacturing (3D printing) allows for the creation of custom-designed tube bundles. This innovation enables engineers to optimize the heat exchange process based on specific system needs, improving overall efficiency and performance.

- Hybrid Materials: The integration of hybrid materials, combining the strengths of non-ferrous metals like copper with other elements such as ceramics, is being studied for higher heat transfer rates, reduced weight, and enhanced resistance to wear and tear.

Future Trends of Non-Ferrous Tube Bundle

- Sustainability and Recycling: With increasing environmental concerns, there is a push towards the development of recyclable non-ferrous materials, such as copper and aluminum. These metals have high recyclability, contributing to reducing the carbon footprint of heat exchangers.

- Smarter Heat Exchangers: The future of non-ferrous tube bundles is tied to smart technology. Sensors embedded within tube bundles can monitor temperature, pressure, and flow rates in real-time, providing critical data for predictive maintenance and performance optimization.

- Energy-Efficient Systems: As industries focus on energy conservation, non-ferrous tube bundles will continue to evolve with an emphasis on improving thermal conductivity and minimizing energy loss. The development of high-efficiency, energy-saving materials will be a key trend.

- Increased Use in Renewable Energy: Non-ferrous tube bundles will play an important role in renewable energy sectors, particularly in geothermal and solar power plants, where their resistance to corrosion and high thermal conductivity are critical.

- Integration with Advanced Cooling Systems: As cooling technology advances, non-ferrous tube bundles will be increasingly used in hybrid cooling systems. These systems combine liquid and air cooling processes, and the non-ferrous tubes’ excellent thermal properties are well-suited to such integrated designs.

Unique Points of Non-Ferrous Tube Bundle

- Superior Corrosion Resistance: Non-ferrous metals, particularly copper and titanium, provide excellent resistance to corrosion in harsh environments like seawater, acids, and chemicals. This makes them ideal for applications in industries such as marine, chemical processing, and wastewater treatment.

- High Heat Transfer Efficiency: Non-ferrous metals like copper have high thermal conductivity, allowing them to transfer heat efficiently, making them particularly effective in heat exchangers for industrial processes.

- Non-Reactive to Aggressive Fluids: Non-ferrous tube bundles are ideal for systems that deal with aggressive fluids, such as acids, saline water, or hazardous chemicals. Their non-reactive nature ensures the integrity of the system without degradation over time.

- Lower Maintenance Costs: The corrosion resistance and fouling resistance of non-ferrous materials mean that these tube bundles require less maintenance and have longer lifespans, reducing the overall operational costs compared to ferrous materials.

- Lightweight: Non-ferrous metals are typically lighter than ferrous metals, which makes the installation of non-ferrous tube bundles easier and reduces the weight of the overall system.

- Better Thermal Expansion Handling: Non-ferrous materials, particularly titanium and copper alloys, handle thermal expansion more effectively, reducing the risk of damage to heat exchangers under high-temperature conditions.

Advantages of Non-Ferrous Tube Bundle

- Corrosion Resistance: Non-ferrous materials like copper, brass, and titanium are highly resistant to corrosion, making them suitable for use in aggressive and marine environments.

- Improved Heat Transfer: Non-ferrous materials, particularly copper, are excellent conductors of heat, improving the overall efficiency of the heat exchanger.

- Durability and Longevity: With their resistance to rust and corrosion, non-ferrous tube bundles last longer than ferrous alternatives, reducing the need for frequent replacements and maintenance.

- Lightweight Design: Non-ferrous metals are generally lighter than ferrous metals, leading to reduced weight in the heat exchanger assembly and easier installation.

- High-Temperature Resistance: Some non-ferrous materials, such as titanium, can withstand high temperatures, making them suitable for high-heat applications.

- Reduced Fouling: The smooth surface of non-ferrous metals tends to accumulate less scale and sediment, minimizing fouling and enhancing performance.

Applications of Non-Ferrous Tube Bundle

- Marine Heat Exchangers: Copper-nickel alloys or titanium are commonly used in marine applications due to their resistance to seawater corrosion.

- Chemical Processing: Non-ferrous tube bundles are ideal for industries dealing with corrosive chemicals and aggressive fluids.

- HVAC Systems: Non-ferrous materials, particularly copper, are used in HVAC systems for heat exchange due to their excellent thermal conductivity.

- Food and Beverage Industry: Non-ferrous materials like copper and aluminum are used in applications requiring sanitary and corrosion-resistant heat exchangers.

- Power Generation: Non-ferrous tubes are used in power plants to manage heat exchange in various processes, especially in high-pressure, high-temperature environments.

Conclusion

Non-ferrous tube bundles are an indispensable part of modern heat exchanger systems, delivering exceptional performance across a wide range of applications. Their corrosion resistance, high thermal conductivity, and long service life make them an ideal choice for industries dealing with aggressive fluids and extreme environmental conditions. As industries continue to focus on energy efficiency, sustainability, and reducing operational costs, non-ferrous materials are expected to play an increasingly important role in heat exchanger technology. Innovations in material science, such as hybrid alloys and nano-coatings, will further enhance the capabilities of non-ferrous tube bundles, ensuring they remain a vital component for achieving optimal heat transfer efficiency and long-term reliability. With their proven track record in demanding applications, non-ferrous tube bundles will continue to drive advancements in heat exchange systems, offering energy-efficient, eco-friendly, and cost-effective solutions for various industries.