Plate Heat Exchangers Principle

Plate Heat Exchangers Principle

A plate heat exchanger is a type of heat exchanger that uses a series of metal plates to transfer heat between two fluids. The principle of operation involves creating an inflow arrangement that maximizes heat transfer effectiveness. Here is a breakdown of the Plate Heat Exchangers Principle.

1. Plate Arrangement

- Plate Construction – The heat exchanger consists of multiple thin, corrugated metal plates. These plates are arranged in a similar manner and separated by gaskets to produce inflow channels for the two fluids.

2. Flow Channels

- Alternate Flow Channels – Fluid A and Fluid B inflow through separate channels formed by the gaps between the plates. These channels are defined by the corrugations on the plates.

3. Entry Points

- Inlets – The two fluids enter the heat exchanger at designated entry points. For simplicity, let’s consider Fluid A as the hot fluid and Fluid B as the cold fluid.

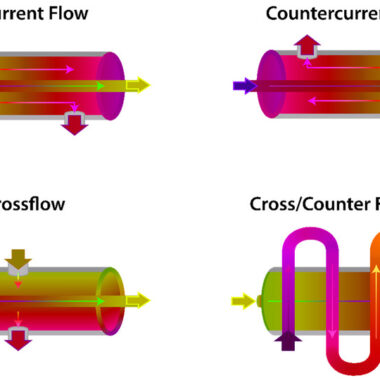

4. Counterflow Arrangement

- Counterflow Design – In numerous plate heat exchangers, the fluids flow in a counterflow arrangement. This means that Fluid A and Fluid B move in opposite directions, maximizing the temperature difference between them throughout the heat exchange process.

5. Heat Exchange Process

- Thermal Contact – As Fluid A and Fluid B flow along their separate channels, they come into close thermal contact through the thin metal plates.

- Heat Transfer Through Plates – Heat is transferred through the plates from the hot fluid to the cold fluid, or vice versa. The corrugated design of the plates enhances turbulence and promotes effective heat exchange.

6. Turbulence and Mixing

- Turbulence Creation – The corrugations on the plates induce turbulence in the fluid inflow, precluding the formation of boundary layers and inhibiting effective heat transfer.

7. Exit Points

- Outlets – After the heat exchange process, the now-hot or cooled fluids exit the heat exchanger through designated outlets.

8. Advantages

- Compact Design – Plate heat exchangers are known for their compact design, offering a large surface area for heat exchange in a fairly small physical footprint.

- High Heat Transfer Coefficient – The turbulent inflow and thin plate construction result in a high heat transfer coefficient, making plate heat exchangers largely effective.

9. Variable Configurations

- Variable Plate Configurations – The arrangement of plates can be adapted to achieve specific heat transfer requirements. This versatility allows for customization based on the application.

10. Applications

- Wide Use – Plate heat exchangers are used in a variety of industries, including HVAC systems, refrigeration, food processing, chemical processing, and power generation.

11. Maintenance

- Ease of Cleaning – The modular design of plate heat exchangers allows for easy disassembly and cleaning of individual plates, minimizing time-outs during maintenance.

Now, Plate Heat Exchangers Principle operate on transferring heat between two fluids through the use of thin, corrugated metal plates. Their efficiency, compact design, and versatility make them a popular choice for a wide range of artificial and marketable applications.

Components of a Plate Heat Exchangers - Cool Fab Equipments April 16, 2024 at 8:49 pm

[…] Plate heat exchangers are wonders of engineering, outlined to proficiently transfer heat between two fluids whereas minimizing energy misfortune. Understanding the key components of a plate heat exchangers devices gives experiences into their functionality and versatility. […]

Applications of Plate Heat Exchangers in Different Industries - Cool Fab Equipments June 24, 2024 at 11:50 pm

[…] Plate heat exchangers (PHEs) are profoundly proficient gadgets utilized to transfer heat between two fluids without blending them. Their compact plan, tall heat transfer proficiency, and adaptability make them suitable for a wide extend of applications over different businesses. Here are a few of the key applications of plate heat exchangers in different industries : […]