Round Cooling Tower Exporters

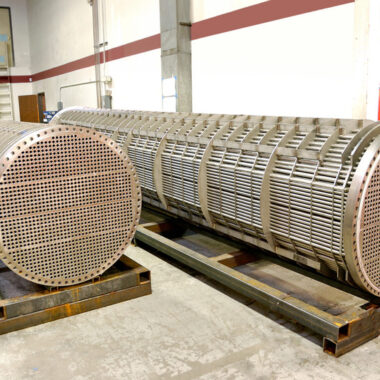

Round cooling tower is using the principle of counter flow current between air stream and water. Sprinkler heads and sprinkler pipes, which are made to revolve by the applied water pressure, are used to disperse water. In order to increase the surface area for heat transfer, hot water travels downward through PVC fills. And forming a thin water film. An axial fan that is mounted on top of the cooling tower draws cooling air in from the outside. The result is a decrease in water temperature. The counter flow current between the air stream and the water will increase air pressure loss. But the efficiency of heat transfer will be better than in other types of cooling towers.

Components Of Round Cooling Tower

Structure

Steel that has been hot-dip galvanized. All connections are made using galvanized bolts and nuts. Plastic reinforced with glass fibers makes up the tower’s walls.

Air inlet mesh

Made of PE plastic to prevent foreign material sucked into tower.

Fan duct

On top of the tower, is made of glass fiber-reinforced plastic (FRP). To increase aerodynamic effectiveness and lessen pressure loss, the shape is cone-shaped.

Motor

The motor will power the tower fan. Our basic tower model often uses a motor that is water and moisture-proof type IP 55 rated due to the humid air stream. If a higher rating is not necessary.

Fan

It’s made of an alloy of aluminium. Water will come into touch with stream air by way of the fan’s created airflow. Axial flow fans are ideal since they can produce a lot of airflow. High efficiency, reduced vibration, corrosion resistance, and safe operation are all requirements for a good fan.

Drift eliminator

Fiberglass-reinforced plastic is used to make this (FRP). It will stop air leaving the tower from bringing over tiny water droplets. It will reduce water loss due to drift.

Basics of Round Cooling Towers - Cool Fab Equipments February 07, 2024 at 4:05 pm

[…] Round cooling towers are famous structures commonly seen in industrial and commercial settings, noiselessly disseminating heat and maintaining ideal working conditions for different forms. Let’s dive into the basics of round cooling towers: […]