Share best practices for maintaining Heat Exchangers

Share best practices for maintaining Heat Exchangers

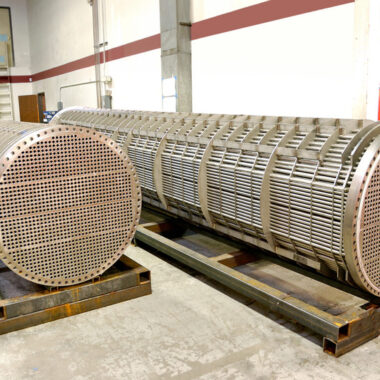

Share best practices for maintaining Heat Exchangers : Appropriate maintenance of heat exchangers is crucial to guarantee their productive operation, life span, and security. Underneath are a few best practices to take after for maintaining heat exchangers:

1. Standard Assessment

Visual Assessment: Routinely assess for any signs of spills, erosion, or physical harm.

Execution Checking: Track execution markers such as temperature differentials, weight drops, and stream rates to distinguish any deviations from ordinary working conditions.

2. Cleaning

Schedule Cleaning: Set up a standard cleaning plan to anticipate fouling and scaling. The recurrence of cleaning depends on the working environment and the sort of liquids utilized.

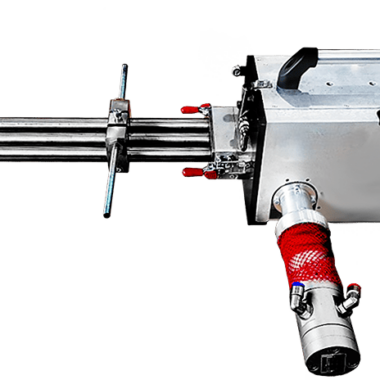

Cleaning Strategies: Utilize fitting cleaning strategies such as mechanical cleaning, chemical cleaning, or hydroblasting. For plate heat exchangers, dismantle and clean person plates on the off chance that essential.

3. Checking and Control

Temperature and Weight Sensors: Introduce sensors to ceaselessly screen the working conditions of the heat exchanger.

Computerized Control Frameworks: Actualize mechanized control frameworks to preserve ideal working conditions and to caution administrators of any irregularities.

4. Preventive Maintenance

Customary Support Plan: Take after a preventive support plan based on the manufacturer’s suggestions and working conditions.

Component Substitution: Supplant worn-out components such as gaskets, seals, and tubes some time recently they come up short.

5. Erosion Security

Erosion Inhibitors: Use appropriate erosion inhibitors within the liquids to play down erosion.

Fabric Choice: Select materials that are safe to the sorts of erosion anticipated in your working environment.

6. Fouling Control

Filtration: Introduce channels or strainers to evacuate particulate matter from the liquids entering the heat exchanger.

Chemical Treatment: Utilize chemical medications to control organic development and scaling within the heat exchanger.

7. Spill Location

Customary Testing: Perform customary spill testing to recognize and address spills early.

Helium or Color Testing: Utilize helium spill discovery or color testing strategies for exact distinguishing proof of spills.

8. Appropriate Shutdown and Startup Methods

Controlled Shutdown: Take after appropriate shutdown strategies to maintain a strategic distance from thermal push and weight surges.

Continuous Startup: Actualize progressive startup methods to guarantee the heat exchanger comes to working conditions easily.

9. Documentation and Records

Maintenance Logs: Keep nitty gritty records of all reviews, cleaning, support exercises, and repairs.

Operational Information: Keep up logs of operational information such as temperatures, weights, and stream rates to track performance trends.

10. Preparing and Security

Administrator Preparing: Guarantee that all faculty included within the operation and maintenance of heat exchangers are appropriately prepared.

Security Conventions: Take after all security protocols and wear fitting individual defensive gear (PPE) amid maintenance exercises.

Conclusion

By following these best hones, you’ll be able altogether improve the effectiveness, unwavering quality, and life expectancy of your heat exchangers. Normal support not as it were makes a difference in anticipating unexpected disappointments but also guarantees ideal execution and security in your operations.