Ultra Flow Exchanger

Introduction

Ultra Flow Exchanger efficient heat transfer is a crucial factor in industrial processes, directly affecting energy consumption, system performance, and operational costs. The Ultra Flow Exchanger is an advanced heat exchanger designed to optimize thermal performance, reduce energy losses, and ensure long-term reliability in demanding environments. Unlike traditional heat exchangers that may suffer from inefficiencies, corrosion, and limited heat transfer capabilities, the Ultra Flow Exchanger is engineered with high-performance materials, advanced flow dynamics, and precision thermal management. These exchangers play a vital role in power plants, chemical processing, HVAC systems, refrigeration, automotive industries, and heavy manufacturing by effectively transferring heat between fluids while minimizing energy wastage. This article explores the key benefits, future innovations, and unique features of Ultra Flow Exchangers, demonstrating why they are a superior solution for modern heat exchange applications.

Key Benefits of Ultra Flow Exchanger

Enhanced Heat Transfer Efficiency

- Designed to maximize heat exchange between hot and cold fluids, ensuring rapid and effective heat dissipation.

- Incorporates advanced turbulence-inducing geometries that increase surface contact area and improve thermal conductivity.

- Reduces thermal resistance and minimizes temperature differentials, leading to faster and more efficient heat transfer.

Energy Efficiency and Cost Savings

- Reduces overall energy consumption by optimizing heat transfer rates and minimizing energy wastage.

- Helps businesses achieve lower operational costs by reducing power consumption in heating and cooling applications.

- Improves fuel efficiency in industrial boilers, refrigeration systems, and thermal power plants, leading to significant cost savings over time.

Compact and Space-Saving Design

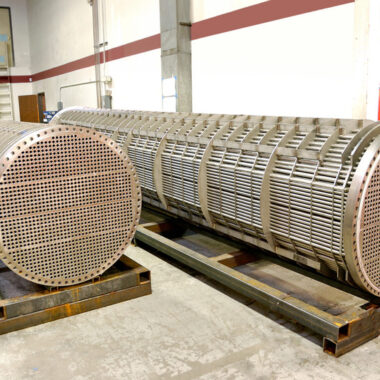

- Features a streamlined, compact structure, making it ideal for space-limited industrial environments.

- Reduces the need for bulky and outdated heat exchangers, freeing up valuable floor space in factories and commercial facilities.

- Enables easy integration into existing thermal systems without requiring extensive modifications.

Durability and Corrosion Resistance

- Manufactured using high-grade stainless steel, titanium, copper alloys, and advanced polymer coatings, which enhance durability and prevent corrosion.

- Resistant to harsh chemicals, high temperatures, and extreme pressure conditions, making it suitable for chemical processing, marine environments, and high-temperature industrial applications.

- Features anti-scaling and anti-fouling coatings, reducing the buildup of deposits and maintaining consistent heat transfer efficiency over time.

Versatility in Applications

- Suitable for a wide range of industries, including power generation, chemical processing, HVAC systems, refrigeration, oil and gas, food processing, and automotive cooling systems.

- Can be customized for specific temperature, pressure, and fluid type requirements, ensuring optimal performance across various industrial settings.

- Supports both single-phase and multi-phase heat exchange, allowing it to handle liquids, gases, and steam-based thermal applications.

Easy Maintenance and Cleaning

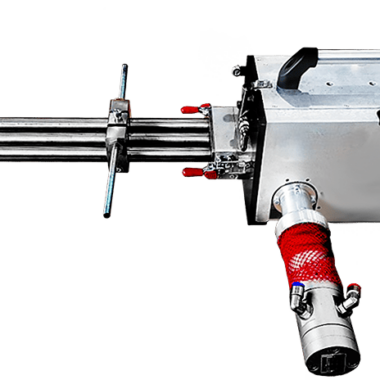

- Modular and detachable design allows for quick disassembly, cleaning, and maintenance, reducing downtime.

- Incorporates self-cleaning mechanisms and anti-fouling technologies to prevent scaling, sludge buildup, and contamination.

- Ensures long-lasting performance with minimal maintenance requirements, making it a cost-effective long-term investment.

Future Trends and Innovations in Ultra Flow Exchangers

Smart Monitoring and IoT Integration

- Advanced IoT-based sensors enable real-time temperature, pressure, and flow rate monitoring for improved efficiency.

- AI-driven predictive maintenance systems detect potential issues before they lead to system failures, reducing unexpected downtimes.

- Integration with cloud-based analytics provides businesses with detailed performance insights and operational data for better decision-making.

Eco-Friendly and Sustainable Designs

- Development of heat exchangers using biodegradable and recyclable materials to reduce environmental impact.

- Use of low-global-warming-potential (GWP) refrigerants and non-toxic heat transfer fluids to support sustainability initiatives.

- Improved energy recovery systems that repurpose excess heat into useful applications, reducing overall energy waste.

Hybrid Cooling Technologies

- Combination of air and liquid cooling mechanisms for enhanced thermal efficiency and energy savings.

- Adoption of phase-change heat exchangers that utilize latent heat transfer for greater cooling performance.

- Research into graphene-enhanced heat exchangers to significantly improve thermal conductivity and heat dissipation rates.

Advanced Nanotechnology Coatings

- Utilization of nanocoatings to improve surface heat transfer rates and enhance corrosion resistance.

- Self-cleaning coatings that prevent scaling, fouling, and microbial contamination, extending the exchanger’s lifespan.

- Improved hydrophobic coatings that increase water repellency and reduce maintenance needs.

Unique Features of Ultra Flow Exchanger

- High-Turbulence Design – Increases fluid mixing and heat transfer efficiency, ensuring minimal thermal resistance.

- Multi-Fluid Compatibility – Can efficiently handle liquids, gases, and two-phase heat exchange processes without performance degradation.

- Leak-Proof Construction – Incorporates advanced sealing technology, preventing fluid leaks and ensuring operational safety.

- Customizable Configurations – Available in various designs, including plate-type, shell-and-tube, and microchannel exchangers, to suit different applications.

- Extreme Temperature and Pressure Flexibility – Engineered to withstand high-pressure steam, cryogenic cooling applications, and superheated gas flows.

- Advanced Thermal Compensation – Features expandable tube designs that allow for thermal expansion without structural stress, preventing wear and tear over time.