Understanding Heat Exchangers

Understanding Heat Exchangers

Heat exchangers are principal gadgets utilized in many businesses to exchange heat between two or more fluids without blending them. They play a basic part in different forms, counting heating, cooling, energy recuperation, and thermal administration. Understanding the fundamental standards, types, instruments, and applications of heat exchangers is basic for selecting and utilizing them successfully.

Basic Principles

The essential work of a heat exchanger is to exchange warm vitality from a more sultry fluid to a cooler fluid. This is often accomplished through a strong obstruction that isolates the fluids but permits heat to pass through. The productivity of this heat transfer depends on variables such as the temperature distinction between the fluids, the properties of the fluids, the surface zone of the boundary, and the stream course of action.

Key Components

Heat Transfer Surface:

The surface zone where heat trade happens. It can be plates, tubes, blades, or other structures.

Fluids:

The hot and cold liquids included within the heat transfer handle.

Stream Arrangement:

The setup of liquid stream, which can be parallel, counterflow, or crossflow, influences the proficiency of heat transfer.

Heat Transfer Instruments

Conduction:

Heat transfer through a strong fabric. The rate of conduction depends on the thermal conductivity of the fabric.

Convection:

Heat transfer between a fluid and a strong surface. Convection can be natural (driven by buoyancy strengths) or constrained (utilizing pumps or fans).

Radiation:

Heat transfer through electromagnetic waves. Whereas less critical in most heat exchanger applications, radiation can be important in high-temperature situations.

Sorts of Heat Exchangers

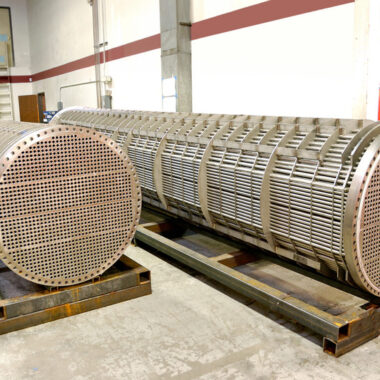

Shell and Tube Heat Exchangers:

Contain a arrangement of tubes enclosed in a shell. One liquid streams through the tubes, whereas the other liquid streams over the tubes inside the shell.

- Points of interest: High-pressure dealing with, robust design, huge surface range.

- Applications: Control plants, petrochemical businesses, oil refineries.

Plate Heat Exchangers (PHEs):

Comprise of numerous thin, layered plates stacked together, shaping channels for liquid stream.

- Advantages: High thermal effectiveness, compact plan, simple capacity development.

- Applications: HVAC systems, nourishment handling, pharmaceuticals.

Finned Tube Heat Exchangers:

Tubes prepared with blades to extend the surface zone for heat transfer.

- Preferences: Improved heat transfer effectiveness, reasonable for gas-to-liquid heat exchange.

- Applications: Air conditioning, car radiators, industrial heat recuperation.

Air-Cooled Heat Exchangers:

Utilize air as the cooling medium rather than water, with finned tubes and fans to upgrade air flow.

- Preferences: No water necessity, lower operational costs.

- Applications: Power plants, chemical preparing, oil refineries.

Double Pipe Heat Exchangers:

Comprise of two concentric channels, with the hot fluid within the inner pipe and the cold fluid within the annular space.

- Advantages: Basic plan, easy maintenance.

- Applications: Little industrial forms, research facility heating and cooling.

Regenerative Heat Exchangers:

Briefly store heat from the hot fluid in a thermal capacity medium and after that transfer it to the cold liquid.

- Preferences: High productivity for heat recuperation, near temperature approaches.

- Applications: Waste heat recuperation, gas turbines, regenerative thermal oxidizers.

Performance Measurements

Heat Transfer Coefficient (U):

Degree of heat transfer rate per unit region per unit temperature difference.

Adequacy :

Proportion of genuine heat transfer to greatest possible heat transfer.

Weight Drop:

Diminishment in fluid weight because it streams through the heat exchanger.

Thermal Capacity:

Sum of heat the heat exchanger can exchange per unit time.

Applications of Heat Exchangers

HVAC Systems:

Heating and cooling air in private and commercial buildings.

Industrial Forms:

Exchanging heat between handle liquids in chemical, petrochemical, and nourishment preparing businesses.

Power Plants:

Steam generation, squander heat recuperation, cooling systems.

Automotive:

Motor cooling, oil cooling, air conditioning.

Renewable Energy:

Heat recuperation in sun based thermal systems, geothermal heating.

Conclusion

Heat exchangers are basic for productive thermal management over different businesses. Understanding the fundamental principles, instruments of heat exchange, sorts, and execution measurements of heat exchangers enables better determination and application, guaranteeing ideal execution and energy effectiveness. Whether in HVAC systems, industrial forms, control plants, or car applications, heat exchangers are vital for viable heat transfer and energy utilization.

Introduction to Industrial Chillers - Cool Fab Equipments July 20, 2024 at 11:38 pm

[…] Heat exchangers play a significant part in different renewable energy systems, upgrading efficiency and empowering effective warm energy exchange. Here’s an introduction to industrial chillers and investigation of their parts in sun oriented thermal systems, geothermal warm pumps, and biomass energy : […]