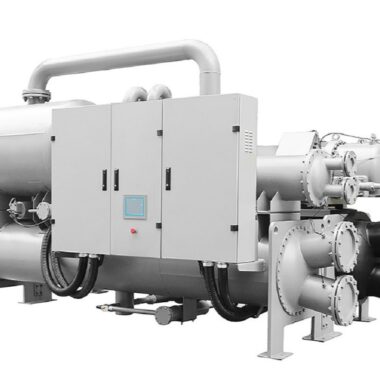

Water-cooled Chillers in India

Water-cooled chillers take heat from a process. After that transmit it to another cooling entity, such as a cooling tower. For high-capacity industrial applications where heat from air-cooled chillers causes a concern. In most cases, cooling towers are utilized in conjunction with water-cooled chillers. Mineral deposit accumulation in the heat transfer circuit can impair heat transfer and lower system effectiveness. As a result, water-cooled chillers usually require condenser water treatment to remove any buildup. Regardless of whether another application or industrial operation calls for a water-cooled chiller. The skilled experts at Delta T Systems guide you in choosing the best water-cooled chiller unit for your application. As well as, they helps to design a unit specifically to meet your needs. With cutting-edge engineering, Delta T Systems gives you the upper hand when it comes to chillers.

NEED FOR WATER COOLED CHILLERS

- Cooling tower water is available.

- Integral pumping is required.

- The air inside is either hot, corrosive, or exceedingly dusty.

- Additional heating serves no useful use.

- The facility has air conditioning.

APPLICATION USAGE

The chemical industry, printing, electronics, plating, the plastics industry, ultrasonic wave cooling, and other fields also make extensive use of water-cooled chillers. Generally, this type of water-cooled industrial chiller can perfectly manage the temperature required by updated machinery production. Also considerably improving productivity and quality. The water-cooled chiller is simple to install. Moreover, comes in a variety of versions.

ADVANTAGES OF WATER COOLED CHILLERS

- Extremely long life and high operational reliability.

- Modularity for a future extension due to an integrated tank and pump.

- All components should be easily accessible for maintenance.

MAIN COMPONENTS

- Hermetic Scroll compressors.

- High efficiency countercurrent shell and tube evaporator.

- Shell and tube condenser.

- Refrigerant pressure gauges and high and low pressure switches.

- Stainless steel pump.

- Insulated pressurized water tank.

- Microprocessor for temperature control.

- Frame and paneling in galvanized steel, hot painted with polyester powders