What are the different types of shell and tube heat exchangers?

What are the different types of shell and tube heat exchangers?

Shell and tube heat exchangers come in different plans and configurations to suit diverse applications and operating conditions. Some of the most common types include:

U-Tube Heat Exchangers:

- U-tube heat exchangers include a bundle of tubes bowed into a U-shape configuration. One conclusion of each tube is associated to a tube sheet whereas the other conclusion is bent into a U-shape. This plan allows for thermal development and compression of the tubes and is commonly utilized in applications with thermal cycling.

Straight Tube Heat Exchangers:

- In straight tube heat exchangers, the tubes run parallel to each other and are associated at both ends to tube sheets. This plan maximizes the heat exchange surface region and is reasonable for high-pressure and high-temperature applications.

Floating Head Heat Exchangers:

- Floating head heat exchangers highlight a coasting tube bundle that can move autonomously of the shell. This plan permits for thermal expansion and contraction of the tubes and encourages simple maintenance and cleaning of the tubes.

Fixed Tube Sheet Heat Exchangers:

- Fixed tube sheet heat exchangers have tube sheets at both closes of the shell, and the tubes are welded or secured to the tube sheets. This plan prevents fluid cross-contamination but may be more inclined to thermal stresses and tube spills.

Kettle Reboilers:

- Kettle reboilers are a type of shell and tube heat exchanger utilized in refining forms. They comprise of a shell with a bundle of tubes submerged in a liquid stage. Heat is exchanged from the tubes to the liquid, causing it to vaporize and produce vapor for the refining prepare.

Bayonet Tube Heat Exchangers:

- Bayonet tube heat exchangers highlight a bundle of tubes that expand through a shell and are supported by a central astound. This plan permits for effective heat transfer and is commonly utilized in high-temperature applications such as steam heating and chemical handling.

Double Pipe Heat Exchangers:

- Double pipe heat exchangers comprise of two concentric channels with one fluid streaming interior the inner pipe and the other liquid streaming within the annular space between the two channels. This plan is simple and compact but may have restricted heat transfer surface range.

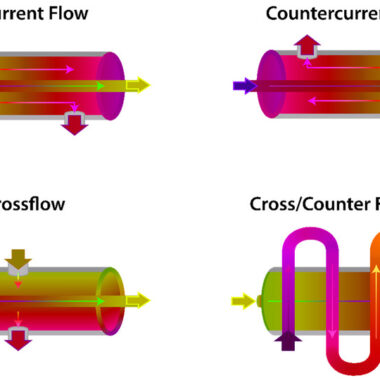

Multi-Pass Heat Exchangers:

- Multi-pass heat exchangers have different passes or circuits for one or both fluids, permitting for expanded heat transfer effectiveness. This plan is regularly utilized in applications where maximizing heat transfer is essential.

These are just a number of cases of the different types of shell and tube heat exchangers accessible. The choice of heat exchanger type depends on components such as the fluid properties, working conditions, space limitations, and execution requirements of the particular application.