Working Principles of Shell and Tube Heat Exchangers

Working Principles of Shell and Tube Heat Exchangers

The working guideline of shell and tube heat exchangers rotates around the productive transfer of thermal energy between two fluids with diverse temperatures. Here’s a breakdown of their working principles of shell and tube heat Exchangers :

1) Heat Exchange Component:

- Shell and tube heat exchangers encourage heat exchange through the dividers of cylindrical tubes. One fluid streams interior the tubes (known as the “tube side”), whereas the other fluid circulates exterior the tubes inside the shell (referred to as the “shell side”).

- Heat exchange happens as the hot fluid interior the tubes exchanges thermal energy to the cooler fluid exterior the tubes. This handle proceeds until both fluids reach a state of thermal equilibrium, where their temperatures equalize.

2) Fluid Flow Path:

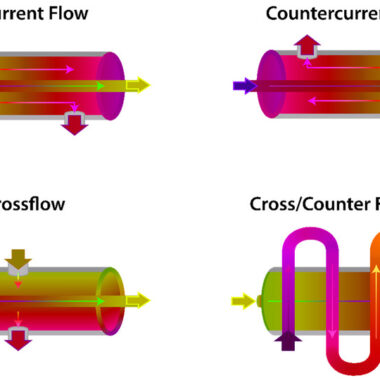

- The hot fluid enters the heat exchanger through an gulf nozzle and flows through the tubes, regularly in a counterflow or parallel stream configuration.

- As the hot liquid travels through the tubes, it discharges heat to the tube walls, warming the encompassing cooler fluid on the shell side.

The heated shell-side fluid at that point exits the heat exchanger through an outlet spout after retaining thermal energy from the hot fluid.

3) Tube Bundle Design:

- The tube bundle, comprising of numerous tubes organized within the shell, maximizes the surface range accessible for heat transfer. This setup upgrades the productivity of heat exchange between the two fluids.

- Baffles or tube supports are frequently consolidated inside the shell to advance turbulence and improve heat transfer effectiveness by coordinating the flow of fluids over the tube bundle.

4) Thermal Performance:

- The proficiency of a shell and tube heat exchanger depends on variables such as the plan of the tube bundle, fluid flow rates, temperature differentials, and the thermal conductivity of the materials utilized.

- Optimal heat transfer is accomplished by guaranteeing legitimate fluid flow conveyance, minimizing fouling and scaling on the tube surfaces, and maximizing the surface region available for heat exchange.

5) Fluid Properties:

- Shell and tube heat exchangers are flexible and can suit a wide range of fluid sorts, counting fluids, gases, and multiphase mixtures.

- The choice of materials for the tubes and shell depends on components such as fluid compatibility, working temperature and pressure, corrosion resistance, and thermal conductivity requirements.

In summary, shell and tube heat exchangers work by encouraging the exchange of thermal energy between two liquids through the dividers of cylindrical tubes. Their effective design, flexibility, and ability to handle different liquid sorts make them indispensable in various mechanical applications requiring heat transfer.